Insights from Above: Advancements in Solar Panel Inspection with Vision AI Drones

- Vathslya Yedidi

- November 24, 2023

Introduction

Solar energy generated by photovoltaic (PV) systems is a major part of one of our sustainable power sources. Despite its numerous benefits, these systems face challenges due to defects in the PV modules due to various environmental factors such as cracked cells, and malfunctions in bypass diodes. These problems necessitate regular inspections to ensure optimal power output is maintained.

This negative impact of solid particles accumulating on the surfaces of solar panels hinders their ability to absorb solar radiation effectively. In dusty or polluted environments, this accumulation can cause a significant decline in efficiency by up to 60% without regular cleaning. To further our global transition to renewable energy sources, it is crucial to address this issue urgently and ensure maximum energy absorption.

Traditional inspection methods, such as visual checks and I-V curve measurements, prove to be time-consuming and imprecise. However, the emergence of Vision AI-powered Drones using Deep Learning algorithms offers an efficient and accurate approach to detecting minor and major defects in PV modules of solar systems. This innovative solution significantly reduces maintenance costs compared to older inspection methods.

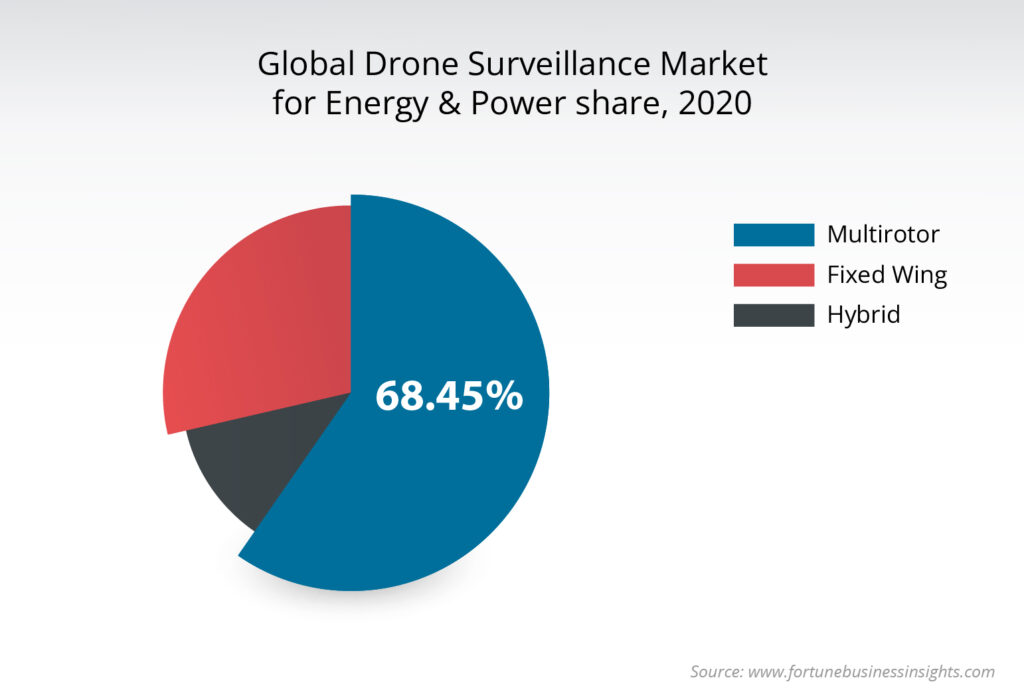

Insights on the Drone Surveillance Market

The use of drones for asset management and infrastructure inspection has seen a significant rise in recent times. This is because drone services are cost-effective, easily maneuverable in remote locations, capable of capturing accurate images using infrared cameras, and equipped with data analysis through ML, and DL algorithms.

Drones are effective in identifying and predicting defects such as corrosion, coating failures, and other structural damages. They are preferred over conventional helicopter inspection methods for various applications such as Solar Panel Inspection, Wind Turbine Inspection, pipeline monitoring, power distribution lines inspection, power plant inspection, and offshore platform inspection.

The Global Drone Surveillance Market for energy and power was valued at USD 118.8 million in 2020 and is projected to reach USD 476.5 million in 2028, with a CAGR of 18.9% during the 2021-2028 period.

Understanding the Complexities of Manual Solar Panel Inspections

Manual inspections of solar panels present various challenges due to the factors involved in the process.

- Safety Concerns: Personnel conducting Manual Inspections often have to climb onto rooftops or structures where solar panels are installed, thereby exposing themselves to potential hazards such as falls, electrical shocks, or other safety risks. Working at heights or in adverse weather conditions can be precarious for inspectors.

- Time Consumption: Manual inspection of solar panels is a time-intensive process, especially for larger installations. The tasks of climbing, individually assessing each panel, and manually documenting findings can consume a considerable amount of time, thereby affecting the overall efficiency of the inspection process.

- Labor-intensive Nature: Manual Inspections typically require skilled personnel to visually inspect each panel, carry out tests, and record data. This can be physically demanding and necessitates a trained workforce, resulting in increased labor costs.

- Variability in Data Accuracy: Manual Inspections can lead to inconsistencies in data accuracy due to human error. Different inspectors may evaluate panels differently, leading to varying levels of accuracy and reliability in the inspection results. Factors such as lighting conditions, experience levels, and subjective judgment can influence the consistency of the collected data.

- Challenges with Repeat Inspections: Achieving consistency in repeat inspections can be challenging when using manual methods. Even the same inspector might evaluate panels differently during different visits, resulting in inconsistencies in data and findings over time.

- Environmental Limitations: Manual Inspections may be constrained by environmental factors such as adverse weather conditions (rain, extreme temperatures, etc.) that can affect the feasibility and safety of conducting thorough inspections.

- Accessibility issues: Some panels may be situated in areas that are difficult to access manually, making it challenging to conduct thorough inspections without specialized equipment or tools.

To overcome these challenges, Drones with Computer Vision are used to enhance efficiency, safety, and accuracy in the Inspection of Solar Panels to provide more consistent and reliable data.

Spotting Issues in Solar Panels Using Vision AI Drones for Better Performance

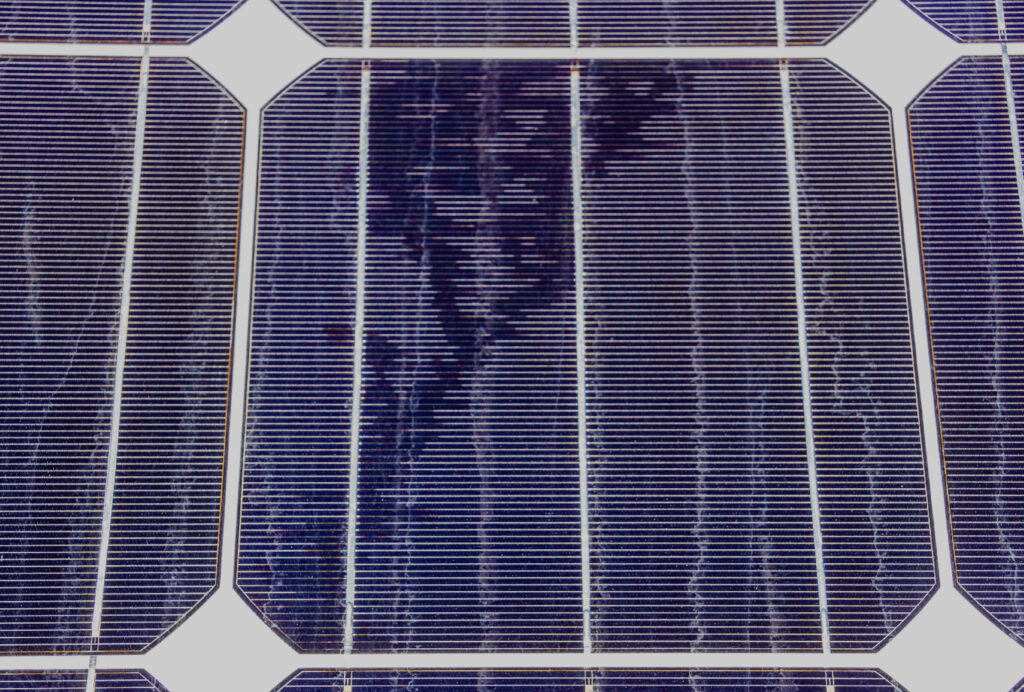

Pollution and Dust Accumulation: Drones equipped with high-resolution cameras can identify pollution buildup and dust accumulation on solar panels. Even a slight accumulation of dust can greatly diminish the efficiency of the panels. . Addressing these issue promptly ensures optimal energy production.

Humidity and Moisture: Thermal imaging sensors on drones can detect areas with higher humidity or moisture ingress, highlighting potential weaknesses in the panel’s sealing and identifying locations prone to corrosion or electrical faults.

Storm or Thunderstorm Damage: After severe weather events, drones can quickly assess damage caused by hail, debris, or other impacts that might compromise the integrity of the panels, such as cracks in glass or structural damage to the array.

Contact Failure and Module Failures: By capturing detailed images of the panels and their connections, drones can identify instances of contact failure, hotspots, or malfunctioning modules that might hinder the efficiency of the system.

Damage from Animal Bites: Birds, rodents, or other animals can cause damage to the panels, which might not be immediately visible. Drones can inspect panels from various angles, spotting signs of damage caused by animal bites or scratches.

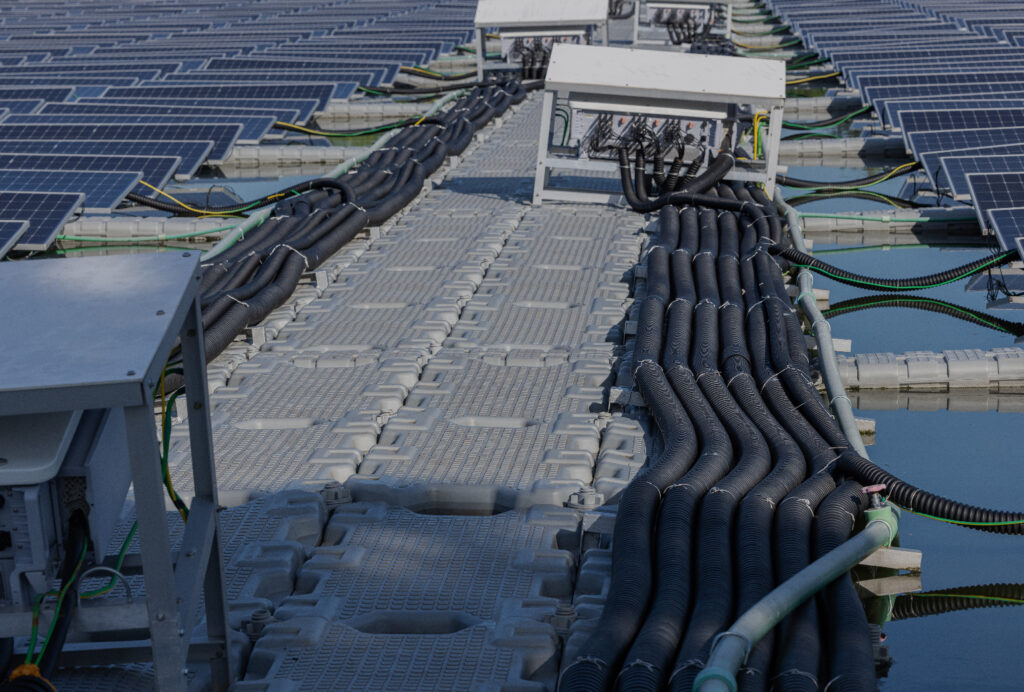

Incorrect Wiring and Defective Bypass Diodes: Drones equipped with specialized sensors can detect anomalies in wiring configurations, highlighting instances of incorrect wiring or malfunctioning bypass diodes that might cause electrical inefficiencies or failures.

How are Vision AI Drones improving the analysis of Solar Panel Defects?

Drone inspection using Vision AI for solar panels involves the use of Computer Vision, Deep Learning algorithms to examine the condition and performance of solar panels. Here’s a general overview of how AI is used in inspecting solar panels:

- Capture Images & Videos: Drones equipped with high-resolution cameras or fixed cameras mounted in specific locations capture images and videos of solar panels. These visual data provide detailed visual information about the panel’s surfaces.

- Data Collection: The visual data collected are processed through Computer Vision algorithms that can detect anomalies, such as cracks, dirt, hotspots, or other issues that could affect the efficiency of the solar panels.

- Defect Detection: Using Computer Vision models, analyze the data to identify any irregularities or defects on the surface of the panels. This could involve Pattern Recognition, Edge Detection, and Image Processing Methods to spot defects.

- Classification and Analysis: Deep Learning algorithms are trained on vast datasets of both normal and defective solar panels. They learn to differentiate between normal and abnormal conditions, allowing for accurate classification of issues and the severity of any detected defects.

- Predictive Maintenance: By continuously analyzing the data and patterns of defects, Vision AI systems can predict potential future issues, enabling proactive maintenance to prevent more significant problems and maximize the panel’s efficiency.

- Automated Reporting: Vision AI-powered Inspection systems generate detailed reports based on the analysis, highlighting areas that need attention or maintenance. This helps operators and technicians quickly identify and address problems, minimizing downtime and optimizing the panel’s performance.

- Integration with Maintenance Systems: These can be integrated into broader maintenance systems, allowing for automated scheduling of repairs, replacements, or cleaning based on priority and urgency.

The benefits of using Vision AI in drones for Solar Panel Inspection increase efficiency, gets faster analysis of large amounts of data, proactive maintenance, reduced costs, and improved energy output from solar installations.

The adoption of Vision AI Drones in Solar Panel Inspections is a significant change in energy maintenance practices. Through these inspections, a thorough data analysis, and reduction in human error, bring a new era of precision, efficiency, and cost-effectiveness in managing solar energy systems. This technological advancement not only improves energy production but also gives way to a more sustainable and resilient energy infrastructure.

Ready to optimize your solar energy system with Vision AI Drone Inspections? Contact us today to schedule a consultation and elevate your solar performance!