Improving Wind Turbine Inspection Accuracy with Vision AI Drone Technology

- Vathslya Yedidi

- October 10, 2023

Wind turbines are widely identified as the most efficient method of generating renewable energy. Given their current installed wind turbine power of 743 GW, their significance in the Global Energy Market cannot be underestimated.

To ensure uninterrupted electricity production and optimal turbine performance, it is crucial to conduct regular inspections. These inspections play a vital role in identifying, detecting, and resolving any structural defects, thereby ensuring smooth and continuous energy generation.

However, given challenging environmental conditions, Windmills often face extreme temperatures and icing which are susceptible to damage. Skilled technicians traditionally perform Visual Inspections to identify defects, but this approach is labor-intensive, time-consuming, and carries significant risks, particularly in unfavorable weather conditions. In some cases, inspections require personnel to scale towering structures and work at extreme heights above sea level, which compromises their safety.

To tackle these difficulties and reduce expenses, the windmill industry is progressively adopting robotic platforms, such as drones, to conduct remote inspections and gather real-time diagnostic data from the entire wind farm. Drones, also recognized as unmanned aerial vehicles (UAVs), are highly automated flying devices that can undertake extended missions, follow predetermined paths, and capture visual information. They are also utilized in various applications, including fisheries monitoring, maritime patrol, terrain mapping, and law enforcement.

This article discusses the significance of Vision AI Drone Monitoring Inspections for Wind Turbines/Windmills where it compares to traditional inspections and highlights how wind farm operators can achieve better optimal performance and reduce energy losses.

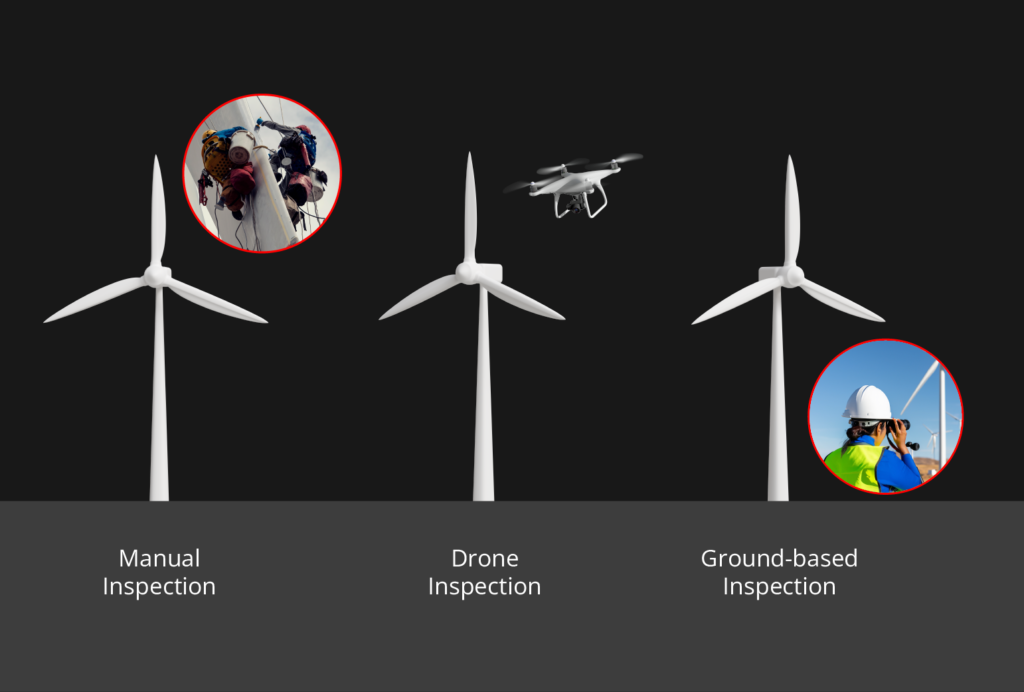

Comparing Wind Turbine Inspection Methods: Traditional, Ground, and Drone Approaches

Traditional (Rope Access) Wind Turbine Inspection methods involve technicians manually climbing the turbine towers to conduct close-up assessments of various components, including the blades, nacelle, and tower structure. These methods can be time-consuming, labor-intensive, and pose safety risks to personnel working at heights. However, they offer a high level of detail and the ability to perform on-site repairs and maintenance but dangerous.

Ground-based Wind Turbine Inspection is conducted from the base of the turbine using visual aids such as binoculars or telescopes. While this approach is less labor-intensive and safer than manual climbing, it has limited visibility and may not detect defects in the upper parts of the turbine. Ground inspection is an economical option, but it does compromise some levels of detail.

Drone-based Wind Turbine Inspection involves the use of unmanned aerial vehicles (UAVs) equipped with high-resolution cameras, thermal imaging, LiDAR, and other sensors. Drones can efficiently fly around the turbine from top to bottom even extending to surrounding areas, capturing detailed images and data from multiple angles.

Drone inspections are known for their speed and efficiency, surpassing traditional methods. This not only reduces turbine downtime but also enhances safety by eliminating the need for personnel to climb towers. Moreover, Drone Inspections are cost-effective in the long run and offer high-quality data for predictive maintenance. Additionally, they provide access to inaccessible areas.

Spotting Wind Turbine Defects Through Drone Imaging

Wind Turbine Defects that can be identified through Drone Inspections are.

- Blade Damage: With high-resolution cameras drones capture detailed images of the turbine blades, enabling operators to identify cracks, erosion, leading-edge erosion, delamination, or other forms of damage on the blade surface.

- Lightning Strike Damage: Wind Turbine Blades may sustain damage due to lightning strikes. Drones can provide a close-up view of any defects caused by lightning, such as burn marks or structural damage.

- Corrosion and Rust: Drones can inspect the turbine tower and metallic components for signs of corrosion, rust, or structural issues, especially in hard-to-reach areas.

- Loose Bolts and Fasteners: Drones equipped with thermal imaging cameras can detect temperature variations that may indicate loose bolts or fasteners in the nacelle and other critical components.

- Oil Leaks: Drones can help identify oil leaks or spillage around the gearbox or other parts of the turbine, indicating mechanical problems.

- Bird Nesting: Bird nests in and around Wind Turbines can cause operational issues and safety concerns. Drones can be used to inspect and document the presence of bird nests.

- Ice and Snow Accumulation: In colder climates, the buildup of ice and snow on turbine blades can affect performance and safety. They can capture images to assess the extent of accumulation and determine if de-icing measures are necessary.

- Environmental Damage: They can monitor the surrounding environment for signs of damage, such as erosion around the turbine’s base.

- Vegetation Management: Additionally, they can also assist in monitoring vegetation growth around the turbine to ensure that it does not impede operational and maintenance activities.

- General Visual Inspection: Drones can efficiently and safely conduct routine Visual Inspections of the entire turbine structure, including the tower, nacelle, and foundation.

Drones reduce the need for hazardous manual climbing and physical inspections. Moreover, they provide detailed imagery and data that can facilitate predictive maintenance and the timely detection of defects, ultimately enhancing the reliability and efficiency of Wind Turbines.

Advantages of Drone-Based Wind Turbine Inspection

Let’s see the advantages when Using Drones for Wind Turbine Inspections:

- Greater Safety: Personnel can remain safely on the ground during Drone-based Inspections, eliminating the need for risky climbs and ensuring the well-being of the inspection team.

- Prompt Inspections: Drone Inspections are highly efficient and can be completed within a short timeframe, ranging from 15 minutes to an hour. This efficient assessment minimizes downtime for the Wind Turbines, allowing them to continue generating clean energy.

- High-Quality Data: These are equipped with various sensors, including high-resolution cameras and Thermal Imaging capabilities. These sensors enable the collection of precise and detailed data, accurately assessing damage size and location.

- Increased Wind Tolerance: They are designed to handle higher wind conditions compared to traditional methods. Built with wind resistance in mind, drones can perform inspections even in strong wind, ensuring consistent data collection.

- Comprehensive Data Collection: Drones offer the flexibility to collect data using visual and thermal sensors. The multi-sensor approach allows for a thorough inspection, with Thermal Imaging revealing issues not visible to the naked eye, such as overheating components or hidden structural damage.

- Repetitive and Consistent: Drone-based Inspections are repeatable and automated, providing consistent data collection and reducing human error. This ensures the reliability of inspection results.

Conclusion:

The efficiency and reliability of Wind Turbines are crucial in the ever-evolving renewable energy landscape. Employing AI-driven Drones for Wind Turbine Inspections is a significant advancement that ensures the success of wind farms. By opting for Drone-based Inspections, operators can enhance safety, obtain high-quality data, and promptly detect and address defects, resulting in minimized downtime and optimized energy production. Embracing Vision AI-driven Drone Inspections is essential as the wind energy sector expands, leading to a more efficient, cost-effective, and eco-friendly future.

Ready to explore how AI-driven Drones can transform your Wind Turbine Inspections? Get in touch to discuss more.