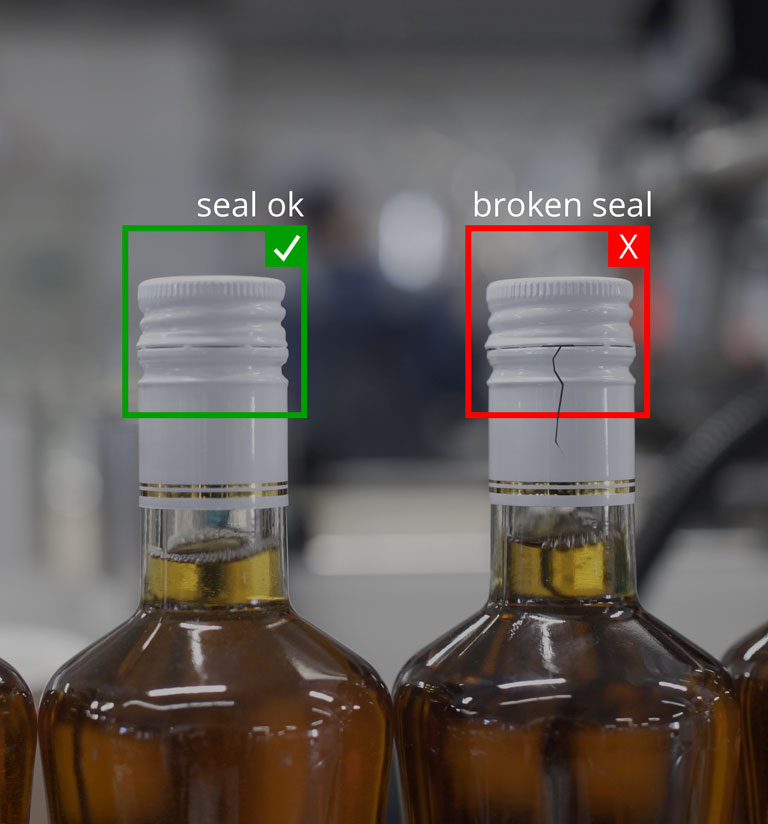

Seal Defect Detection

Bottle Seal Integrity through Seal Defect Detection with Vision AI

Precisely and efficiently identify seal defects such as leaks, cracks, pinholes, and deformities through high-resolution imaging and Deep Learning algorithms. Enhance your quality control process, ensure product integrity and minimize wastage.

Overcome Challenges in Seal Defect Detection for Bottle Caps Using Vision AI

Manual inspection methods are often time-consuming and result in human error and an increase in production costs.

- Achieve Products Safety: Products may undergo damage from shipping and handling which could spoil the product.

- Production and Development Pause: Production may stop for quality or brand issues.

- Contamination of Products: Poor sealing leads to contamination and the formation of foreign bodies.

Bottle Seal Defect Detection with Vision AI for Better Quality Control

Reduce the production cost, improve production efficiency and product quality with our Deep Learning algorithm.

- Image Acquisition: High-quality images are acquired through cameras.

- Pre-process: Improve image quality by preprocessing, filtering, contrast enhancement, and noise reduction.

- Defect Detection: With a Deep Learning algorithm, defects are detected and classified, with a report generated at the end.

Enhance Seal Inspection and Seal Integrity Testing with Vision AI

Ensure your product’s safety and reliability by detecting and addressing seal defects and inconsistencies. Improve your seal inspection processes proactively with Vision AI and provide long-term product excellence and customer satisfaction.

Uncover Valuable Patterns and Insights

Get a QuoteGet a Quote

×