Quality Verification

Transform Your Quality Verification with Vision AI

Maximize product quality, throughput, and cost savings with Vision AI Quality Verification. Enhance your quality assurance process, improve efficiency, and achieve unparalleled excellence in your operations.

Navigating the Challenges of Quality Verification with Vision AI

Organizations strive to keep up with evolving quality standards and regulations, leading to difficulty in adapting verification processes.

- Quality Standards: To meet and maintain required quality standards of products.

- Implement Better Quality Control Process: Implement quality control measures to prevent defective products from reaching customers.

Elevate Quality Assurance with Computer Vision

Comprehensive evaluations and examinations to secure the safety, uniformity, and alignment with standards of food items.

- The process encompasses visual examinations.

- State-of-the-art technology identifies extraneous materials, while precision and adherence to regulations are verified during inspection.

- The significance of hazard analysis is underscored, and this systematic procedure fosters ongoing enhancement.

- In essence, quality inspection assures the safety, excellence, and credibility of food products for consumers.

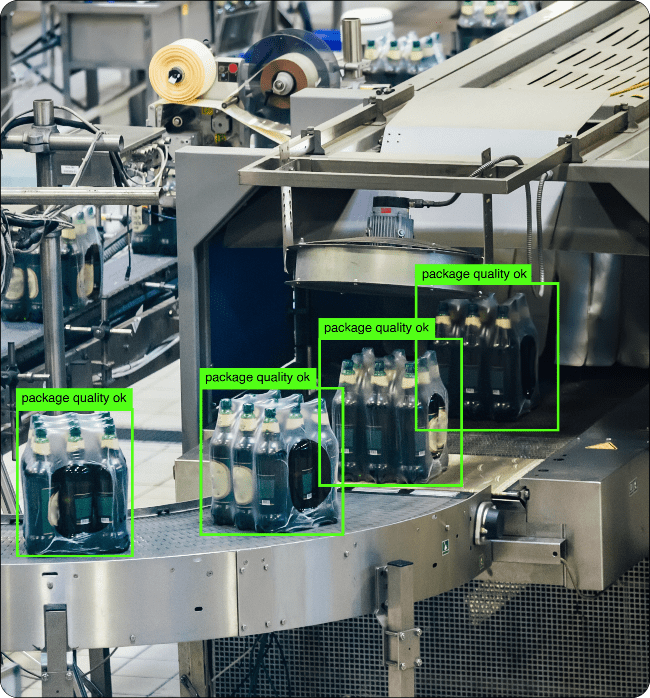

Fast-Track Your Quality Verification with Deep Learning

Streamline your quality verification process and ensure your brand meet the highest standards of quality and safety.

- Surface Defect Detection: Identify and classify defects or irregularities on the surface of a material or product.

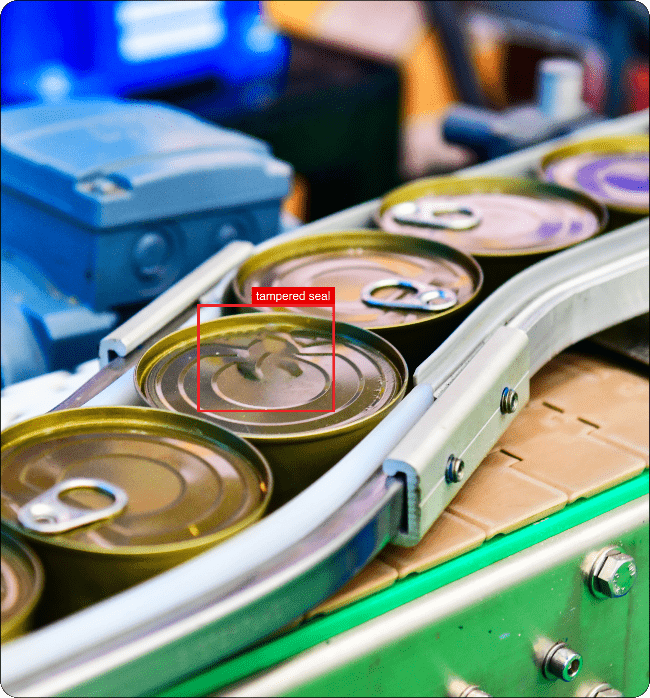

- Tamper Detection: Identify when a package has been opened or resealed after the initial packaging.

- Fill Level Detection: Ensure your products such as bottles, cans, or other containers are filled to the correct level.

- QR/Bar Code Label Inspection: Detect any printing defects, such as smudging, blurring, or incorrect printing, that could impact the readability of the barcode.

- Foreign Particle Detection: Detect and remove any foreign objects or particles in a product such as metal shavings, plastic, dirt, or other debris.

- Seal Inspection: Detect defects in seals of packages, such as bags, pouches, or trays.

- Cap Closure Inspection: Check if the bottle, can, or container caps are sealed properly.

- Object Counting: Automatically count the number of objects in an image or video.

- Dimension Inspection: Measure and verify the physical dimensions of an object.

- Thermal Seal Inspection: Detect defects in the thermal seals of packages, such as bags, pouches, or trays.

Renovate Quality Standards with Computer Vision Quality Verification

With our precise quality evaluation and prompt defect detection, businesses can optimize their processes and deliver exceptional products consistently. Our system enables real-time analysis, ensuring immediate corrective actions and minimizing waste. Elevate customer satisfaction by partnering with us to revolutionize your quality control processes.