From Imperfections to Perfection: The Role of Dimension Detection in Biscuit Shape Inspection

- Vathslya Yedidi

- February 27, 2024

Every biscuit produced in a manufacturing line must meet strict size and shape specifications to ensure consistency, quality, and regulatory compliance. Even the slightest deviation in ingredient levels, dough consistency, or baking conditions can impact the final product’s dimensions, affecting consumer satisfaction and packaging efficiency.

Traditional measurement methods, such as manual inspection and mechanical gauges, struggle to keep up with the precision demands of modern production. Manual checks are slow and prone to human error, while mechanical tools cannot detect subtle variations at high speeds.

As a result, manufacturers are turning to Computer Vision solutions to enhance quality control and optimize efficiency. Biscuit dimension detection with Vision AI offers a better solution for precise and automated inspection, addressing the limitations of traditional methods.

The Importance of Consistent Biscuit Dimensions in Manufacturing

The primary goal of keeping biscuit dimensions during manufacturing is to meet customer expectations and product consistency. Consumers expect every piece to be identical when they open a package of biscuits. Here’s why maintaining uniform biscuit dimensions is crucial:

- Regulatory Compliance: Biscuit dimension detection is critical for adhering to food labeling regulations that mandate specific weight and size tolerances. Compliance is not just recommended; it is a legal requirement. Failure to meet regulations can result in penalties, recalls, and damage to brand reputation.

- Optimized Production Processes: Biscuit dimension inspection helps manufacturers quickly detect inconsistencies, minimizing waste, reducing downtime, and improving resource efficiency. This proactive approach enhances production efficiency and cost savings.

- Improved Consumer Experience: Precisely dimensioned biscuits create a visually appealing and satisfying eating experience. Consumers appreciate uniformity in portion sizes, ensuring they receive the expected product quality every time.

- Packaging Efficiency and Protection: Uniform biscuit dimensions ensure a proper fit in packaging, allowing for secure sealing, even stacking during transport, and reduced material waste. This consistency improves packaging integrity, prevents breakage, and efficiency.

How To Measure Biscuit Dimensions Using Computer Vision?

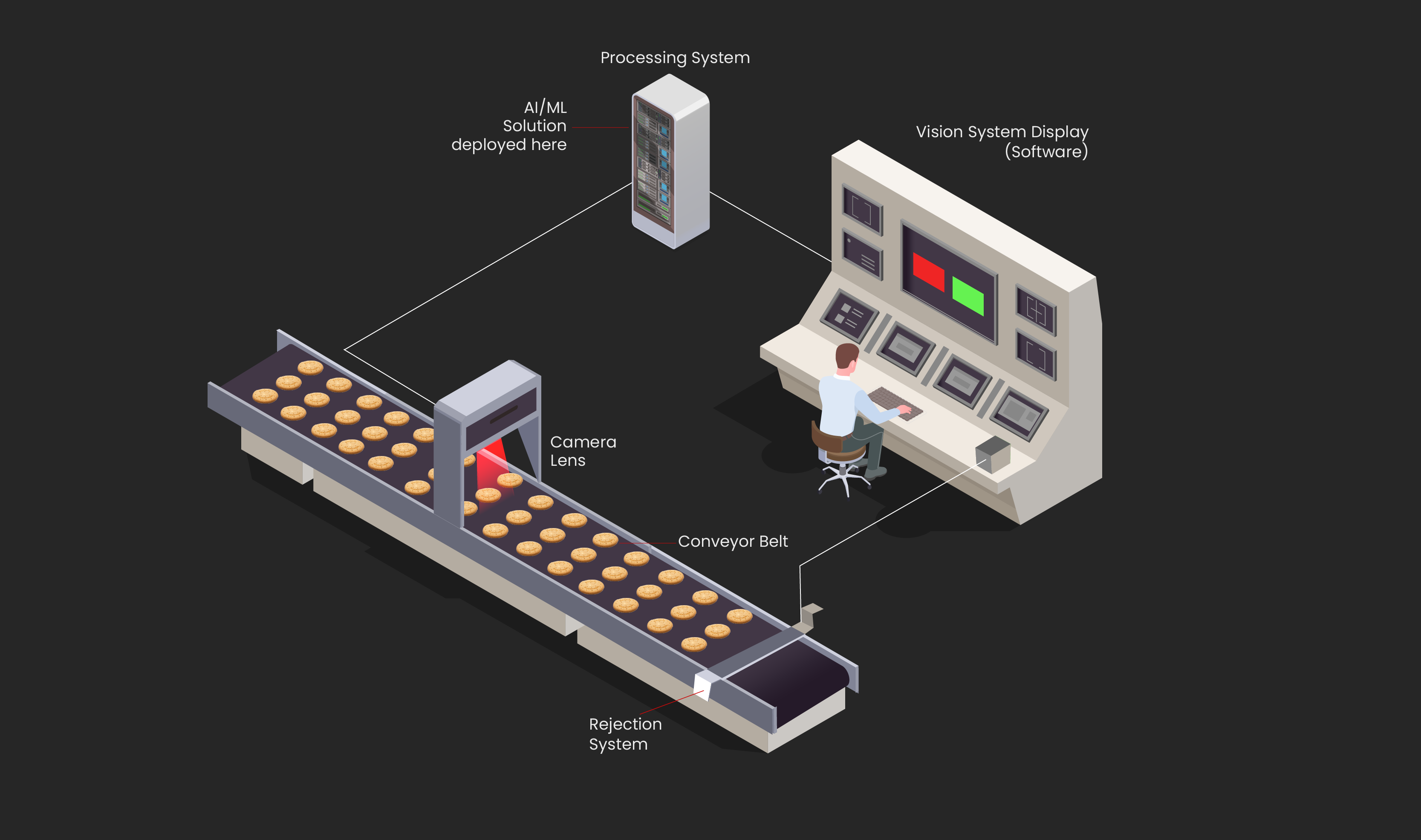

The biscuit dimension inspection system leverages imaging and Computer Vision algorithms to ensure consistent product quality and optimize production efficiency.

- Intelligent Image Acquisition: High-resolution cameras strategically placed along the production line capture multiple images of biscuits in real-time. This multi-angle approach ensures comprehensive dimensional analysis, accounting for variations in biscuit orientation and minimizing the impact of shadows or lighting inconsistencies. The system can be easily adapted to different production line speed and configurations.

- Robust Image Preprocessing: Sophisticated algorithms preprocess the captured images, enhancing clarity and isolating individual biscuits. This crucial step addresses challenges like overlapping products, complex shapes, and varying lighting conditions. Advanced segmentation techniques accurately separate biscuits from the background, ensuring precise measurements even in challenging scenarios.

- Precise Dimensional Feature Extraction: Algorithms extract precise dimensional data, including length, width, height, diameter (for round biscuits), and other relevant shape characteristics. It can be trained to recognize and measure specific features relevant to diverse biscuit shapes and sizes. This adaptability makes it suitable for a wide range of biscuit products.

- Intelligent Comparison with Standards: The system automatically compares extracted biscuit dimensions against predefined quality control parameters. Adjustable tolerance ranges allow customization for different biscuit types and sizes, ensuring flexibility in production. This adaptability helps manufacturers maintain consistency, meet quality standards, and quickly adjust to changing product specifications or customer preferences.

- Real-Time Automated Rejection: Biscuits that fall outside the acceptable tolerance range are instantly flagged for rejection. This automated process removes the possibility of human error and ensures that only products meeting the required dimensions proceed to packaging. Real-time feedback enables immediate adjustments to the production process, minimizing waste and maximizing efficiency. This process of biscuit dimension detection with Vision AI ensures consistent product quality and minimizes production losses.

Identifying Dimensional Defects with Vision AI

Biscuit dimension detection for accurate measurement using Computer Vision analyzes various dimensional aspects of each biscuit, identifying even subtle deviations from the ideal. This precise analysis allows for the detection of several key dimensional defects:

1. Length and Width Inconsistencies

Vision AI can detect variations in the length and width of biscuits, ensuring uniformity within a batch. This is crucial for consistent portioning and packaging. For example, if biscuits are slightly too long or too short, it can affect how they fit in the packaging.

2. Thickness Variations

Inconsistent thickness across a biscuit can affect baking consistency and texture. Vision AI can detect these variations, ensuring uniform baking and a consistent eating experience. A biscuit that is thicker in one area than another will bake unevenly.

3. Shape Irregularities

Deviations from the intended shape, such as warping, twisting, or uneven edges, can impact visual appeal and packaging efficiency. Vision AI algorithms can analyze the overall shape and identify these irregularities. For example, a warped biscuit may not fit properly in its packaging.

4. Diameter/Circularity Issues (for round biscuits)

Maintaining a consistent diameter and circular shape is crucial for round biscuits. Vision AI can identify deviations from the ideal circular form or variations in diameter, ensuring that the biscuits meet the required specifications. An out-of-round biscuit might not fit into standard packaging or appear visually unappealing.

The Benefits of Computer Vision for Biscuit Dimension Measurement

Implementing Computer Vision for biscuit dimension measurement offers numerous compelling advantages:

- Better Accuracy: Computer Vision systems provide highly accurate dimensional measurements, significantly surpassing manual inspection. This precision is essential for maintaining consistent product quality, meeting regulatory requirements, and minimizing product waste.

- Improved Throughput: Automated biscuit dimension measurement with Computer vision dramatically increases inspection speed, allowing manufacturers to process large volumes quickly and efficiently. This translates to higher production capacity and faster time to market.

- Real-Time Monitoring and Control: The system provides real-time data on biscuit dimensions, enabling immediate identification and correction of production line deviations. This proactive approach prevents large-scale quality issues and reduces the need for costly rework.

- Data-Driven Insights for Continuous Improvement: The dimensional data can be analyzed to identify trends, optimize production parameters, and refine product design for greater consistency. This data-driven approach empowers manufacturers to make informed decisions and continuously improve their processes.

Conclusion

Consistent quality is the cornerstone of a strong brand reputation in the biscuit industry. Vision AI empowers manufacturers to achieve this through precise, automated dimension inspection, ensuring every biscuit meets strict size and shape standards. This leads to happier customers, increased brand loyalty, and a stronger market position.

Contact us today to explore how Vision AI can change your biscuit dimension Inspection