Beyond Human Capabilities: The Role of Vision AI in Packaging Quality Verification

- Vathslya Yedidi

- July 31, 2023

In today’s rapidly advancing technological landscape, the integration of automation for quality checks has emerged as a pivotal factor in enhancing product quality, productivity, and efficiency across diverse industries. Among the sectors witnessing notable progress in Automated Quality Verification is packaging, where the implementation of Computer Vision technology has revolutionized traditional manual quality check procedures. In the past, packaging processes heavily relied on labor-intensive tasks, leading to time-consuming operations and an increased risk of errors. However, the advent of Computer Vision has prompted businesses to shift their attention toward automation and optimization in quality control procedures.

Based on predictions, the AI market within the packaging industry is projected to reach a worth of US$2,080.8 million by 2023 and is foreseen to further expand to US$6,015.6 million by 2033. Over the forecast period, AI sales in packaging are anticipated to experience significant annual growth at a rate of 11.20%.

This blog post will delve into the benefits of Vision AI Quality Verification in packaging, highlighting how this technology is transforming the industry and enhancing quality control and operational capabilities.

The Manual Packaging Challenge

Before the emergence of Computer Vision, manual packing processes were fraught with challenges. No matter how skilled and diligent, the human workforce was prone to making errors. Packaging accuracy suffered factors such as fatigue, distractions, and the limitations of human vision in detecting specific defects or variations in product quality. As a result, these inaccuracies resulted in product waste, escalated production expenses, and left customers dissatisfied.

Understanding Computer Vision in Packaging

Computer vision is a subset of artificial intelligence that interprets visual information from cameras or sensors. It uses image processing and pattern recognition techniques to automate quality checks in packaging processes, improve efficiency, accuracy, and quality control.

Common Errors Often Observed in Packaging Quality Verification

Packaging errors can occur in the production process due to human error, equipment malfunction, or other factors. These errors can result in compromised product quality, safety concerns, increased costs, and negative customer experiences. Some common packaging errors include:

- Incorrect Labeling: Incorrect labeling is a common packaging error involving wrong names, barcodes, dates, and missing information. It can cause non-compliance and safety risks.

- Damaged Packaging: Damaged Packages during transit or mishandling, resulting in torn, dented, or crushed packaging. Damaged packaging affects the product’s appearance and may expose it to contamination or spoilage.

- Seal Integrity Issues: Improper or faulty seals can cause leakage, spoilage, or tampering with the product, especially in food and pharmaceutical products where compromised seals can be a safety hazard.

- Incorrect Quantity: If the number of products in the packaging does not match the intended quantity, it can lead to customer dissatisfaction and complaints.

- Inconsistent Package Appearance: Inconsistent colors, logos, or packaging graphics create negative impressions and may raise concerns about product authenticity or quality.

- Inaccurate Package Dimensions: Packaging that is not an accurate representation of the product’s dimensions can result in inefficient use of shelf space, leading to additional costs for storage and transportation.

- Incorrect Packaging Materials: Using improper packaging materials, such as a non-food-grade container for food products compromises the safety of the product and its compliance with regulations.

- Expiry Date Errors: Incorrectly printed or missing expiry dates can lead to the sale of expired products, causing health risks and potential legal issues.

Incorporating Vision AI Inspection for quality control in your manufacturing operations ensures packaging accuracy and integrity of the products.

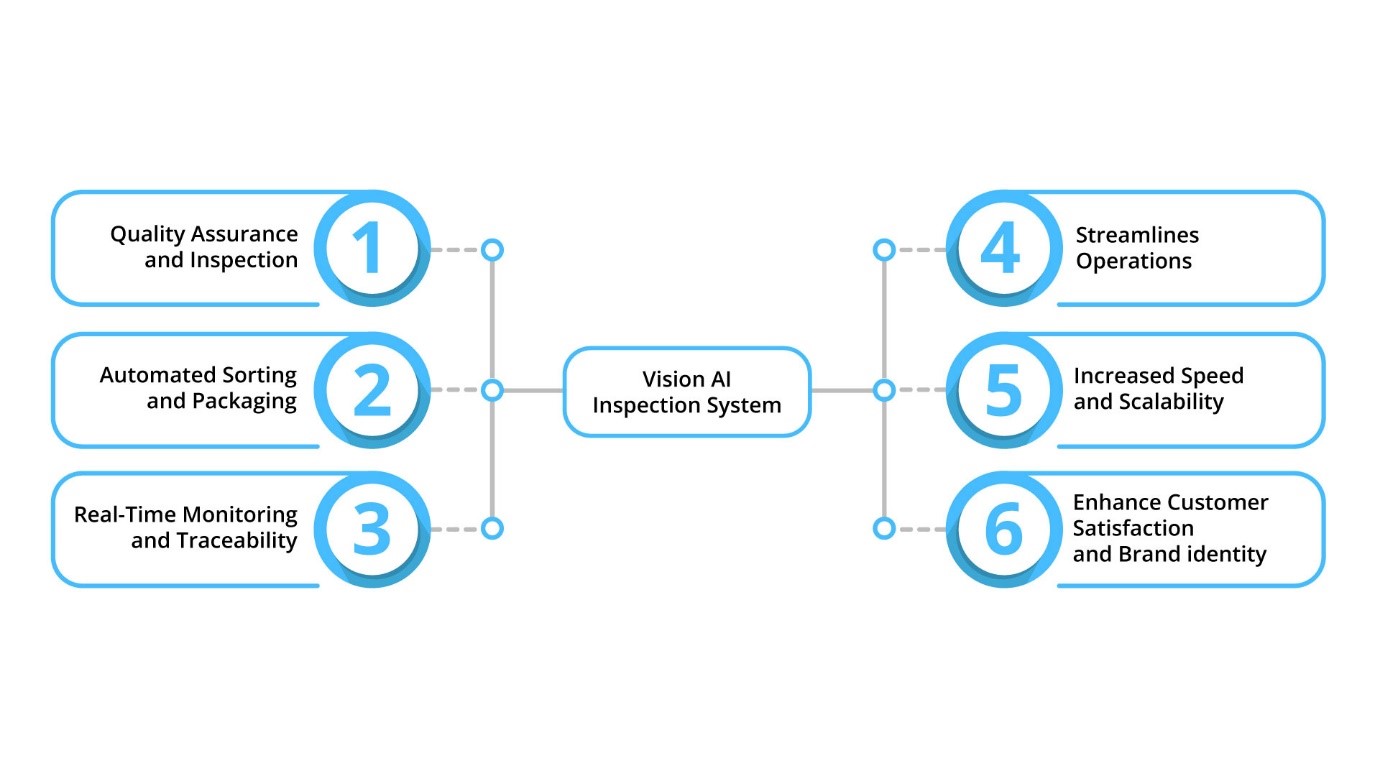

How does Vision AI Inspection improve packaging operations?

To enhance quality assurance and reduce production downtime certainly, manufacturing, FMCG companies need reliable packaging Quality Verification solutions to improve their operations. Check here how Vision AI Inspection System is improving the Quality Verification operations.

1. Quality Assurance and Inspection

Ability to enhance quality assurance and inspection processes. With high-resolution cameras and Deep Learning algorithms, Vision AI Inspection System detects defects, imperfections, or damage in products and packaging materials with great accuracy. This ensures that products that meet the required quality standards are allowed to proceed further in the packaging pipeline, reducing waste and minimizing customer complaints.

2. Automated Sorting and Packaging

Facilitates automated sorting and packaging operations. Various products and their unique characteristics, such as shape, size, and color, can be recognized, enabling packaging machines to sort and group them accordingly. This leads to a significant improvement in the speed and efficiency of the packing process, reducing bottlenecks and streamlining overall operations.

3. Real-Time Monitoring and Traceability

Businesses gain real-time monitoring capabilities, enabling them to keep a close eye on the entire Quality Verification packaging process. This allows for swift identification of any issues or discrepancies, preventing them from escalating into larger problems. Moreover, Computer Vision provides end-to-end traceability, allowing companies to track each product’s journey through the packaging line, improving accountability and recall management.

4. Streamline Operations

Human error, fatigue, and limitations in speed and accuracy can cause inefficiencies. Computer Vision automates manual tasks and improves efficiency by analyzing visual data to recognize and classify products, determine dimensions, and assess the condition in real time. This enables informed decisions on packaging materials, container sizes, and packing configurations, optimize space utilization and minimizes waste.

5. Increased Speed and Scalability

Automated Quality Verification in packaging with Computer Vision is faster and more efficient than manual labor. They can process items quickly and accurately, meeting increasing demand and improving order fulfillment rates. With parallel processing capabilities, multiple items can be assessed and packed simultaneously, enhancing speed and scalability.

6. Enhance Customer Satisfaction and Brand identity

A positive customer experience is key in building brand loyalty and trust. Vision AI Inspection enhances customer satisfaction by ensuring high-quality standards are consistently met. Reliable packaging builds consumer trust and offers personalized experiences through AI-driven analysis, strengthening the bond between brands and customers.

Conclusion

With defect detection, automated sorting and packaging, and real-time monitoring, Vision AI remodels Packaging in improving Quality Verification, operational speed, and productivity. Embrace Computer Vision in packaging quality check operations to boost efficiency, reinforce brand identity, and cultivate customer loyalty through consistent, high-quality packaging.

Ready to streamline your packaging quality verification operations by leveraging the benefits of Vision AI solutions? Contact us now to discover how our Computer Vision solutions can boost your quality Control, efficiency, and customer satisfaction. Stay ahead in the fast-paced packaging industry with Vision AI and let us drive your business success.