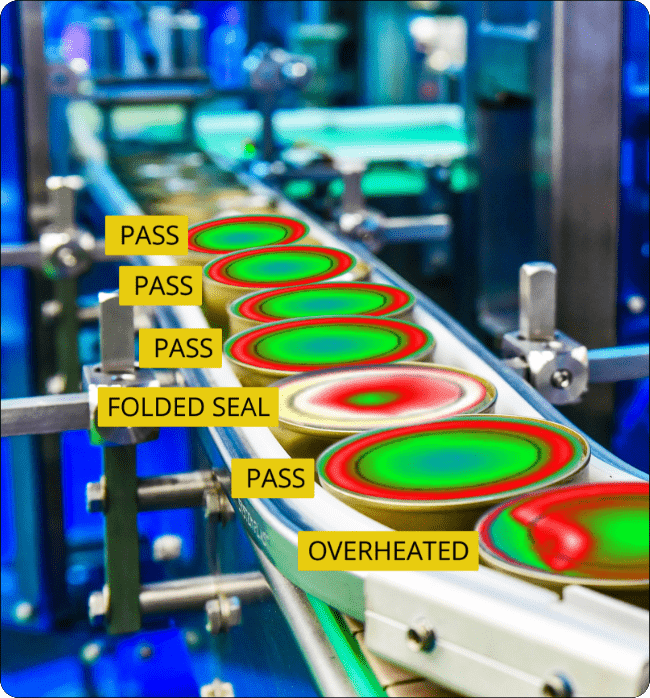

Thermal Seal Inspection

Spot Seal Defects Through Thermal Seal Inspection with Vision AI

Sealing is important in preserving product freshness, preventing contamination, and maintaining the quality of packaged goods. With Machine Vision thermal seal inspection algorithm, easily detect and analyze seal imperfections with unparalleled precision. Elevate your packaging quality control to secure your products and exceed customer expectations.

Navigating the Challenges of Thermal Seal Inspection to Enhance Product Safety Assurance

With human inspection, it is difficult to prevent defects that are invisible.

- Contamination: Formation of contamination and foreign bodies due to poor sealing.

- Production Halts: Production halts due to quality control, system failure, and bad brand issues.

- Safety of Products: Contamination spoils the freshness and safety of products.

Automate Quality Control with Thermal Seal Inspection

The Thermal imaging system detects heat patterns along the seal lines and analyzes them to identify inconsistencies or defects in the sealing process.

- Analyzing images of the heated region determines temperature variations that could signal potential seal defects or irregularities.

- Examining these images meticulously(thoroughly) to pinpoint anomalies, including incomplete seals, leaks, or regions with inadequate bonding.

- Utilizing the insights gained from analysis and interpretation, decision-making for rejection is processed and serves as a record of the inspection process and its outcomes.

Boost Packaging Reliability with Thermal Seal Inspection using Computer Vision

With our automated Thermal Seal Inspection system, you can streamline your quality control operations and ensure that every sealed product meets the highest standards. Simplify quality control, reduce labor costs, optimize resource allocation for manufacturers, and deliver high-quality products to your customers.