Defect Detection

Defect Detection with Vision AI

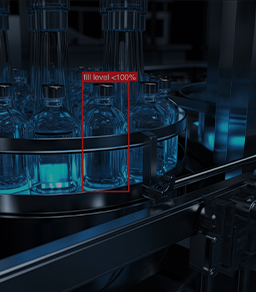

Ensuring the integrity and safety of products is essential. Defect Detection is crucial, as it identifies and resolves any manufacturing and packaging problems to ensure the highest quality results. With Vision AI inspection process we can enhance the detection of irregularities in pharmaceutical products such as tablets, capsules, vials, and syringes. It effectively detects chips, cracks, and abnormalities, thus ensuring that patients receive medications of the highest possible quality.

Implementing Accurate Defect Detection Using Computer Vision for Medication Packaging Analysis

Challenges in the pharmaceutical industry often arise when it comes to traditional Defect Detection processes due to limitations in conventional inspection methods because they can be susceptible to setbacks that compromise quality control. Some key issues associated with manual inspection include:

- Variability and Human Error: Manual inspections are prone to human errors, resulting in discrepancies and unreliable identification of product defects.

- Inspector Fatigue: With time, human inspectors may experience a decline in vigilance due to fatigue, potentially impairing their ability to detect defects and compromising the quality of pharmaceutical products.

- Inefficiency: Traditional inspection processes consume a significant amount of time and labor, leading to production delays and an increased risk of defective products infiltrating the market.

- Overlooking Minor Imperfections: The human eye can overlook subtle yet critical defects due to essential limitations in visual acuity and sustained attention to detail.

Guarantee Product Integrity Using Defect Detection with Vision AI

Implement Vision AI to accurately detect defects during pharmaceutical production, ensuring flawless products pass through the production line.

- Image Acquisition: High-resolution cameras thoroughly capture images of pharmaceutical products from multiple angles.

- Image Processing: Algorithms preprocess the images to enhance clarity and remove distortions, preparing them for detailed analysis.

- Feature Analysis: Vision AI examines the images to detect anomalies and extract relevant product features such as shape and texture.

- Defect Identification: Using trained Deep Learning models, identify defects and classify them such as cracks, misshapen pills, or incorrect labeling.

- Quality Assessment: The system evaluates the products against quality standards and segregates any defective items for removal or further manual inspection.

Guarantee Product Quality with Defect Detection Using Vision AI

Our Defect Detection capabilities ensure that every product meets the highest quality standards before distribution.

- Surface Imperfections: Detect surface defects such as scratches, dents, discolorations, or irregularities on products.

- Dimensional Variations: Identify dimensional defects by analyzing the size, shape, and alignment of products.

- Assembly and Alignment Issues: Identify defects related to assembly, such as misalignments, incorrect placements, or missing components.

Elevating Product Integrity with Defect Detection Using Vision AI

Improve your Defect Detection process with Deep Learning algorithms, enabling the identification and removal of faulty products from the production line to ensure unparalleled product quality and safety.