Cap Closure Inspection

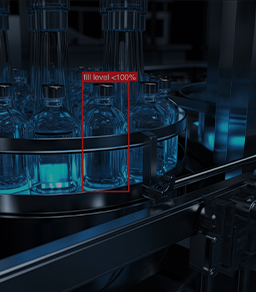

Advance Product Sealing Safety Using Cap Inspection with Computer Vision

Advance your production process with uncompromised quality control. By automating the cap closure inspection, you can significantly increase production speed, reduce labor costs, and minimize the risk of human errors.

Navigating the Challenges of Cap Closure Inspection for Product Safety

Manual inspection can result in missed defects and false inspections due to human error

- Cap Variations: Caps come in different sizes, shapes, and colors, which can make it challenging to inspect them accurately.

- Product Safety and Quality: Prevent contamination and ensure product efficacy.

- Finding Defects: Manufacturing defects such as cracks, chips, and misalignments can occur, making it difficult to detect them consistently.

- Production Line Speed: High-speed production lines can make it challenging to inspect caps accurately and quickly, leading to errors and product defects.

Safeguard Product Integrity with Automated Cap Closure Inspection

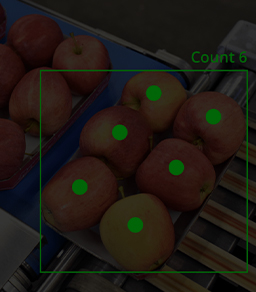

Leverage Deep Learning algorithm to inspect bottle caps and detect common defects such as contamination, flash, short shots, and tamper-evident band issues.

- Cap Feeding: Caps are fed into an inspection system.

- Cap Orientation: Caps are positioned for inspection and aligned with the equipment.

- Image Process: Images of the caps are analyzed for defects using DL algorithms.

- Defective Caps Rejection: Rejected caps are removed from the production line using air jets or mechanical arms.

Refine Quality Verification Process with Cap Closure Defect Detection Using Vision AI

Minimize the risk of faulty closures with Vision AI and prevent product waste, reduce the chances of product recalls, and protect your brand identity.

Uncover Valuable Patterns and Insights

Get a QuoteGet a Quote

×