Leak Detection

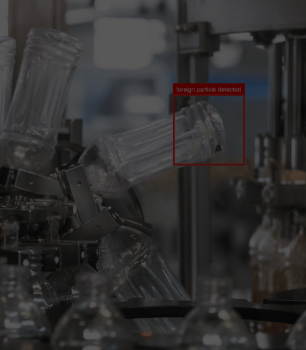

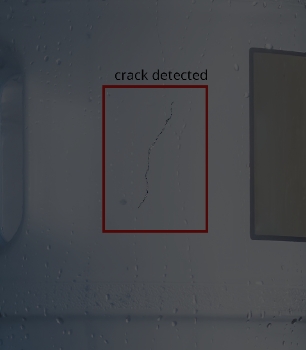

Detect, Prevent Product Leaks, and Improve Quality Control with Visual Inspection

Implement Visual Inspection into your quality control process for safety and quality of your products. With Computer Vision algorithms detect leaks that may not be visible to the naked eye and reduce the risk of contamination and product leaks, ensuring that your products meet the standards of quality.

Overcome Leak Detection Challenges with Computer Vision for Food Safety

Threat to Business operations that may cause a bad reputation due to bad product quality which can even threaten business survival.

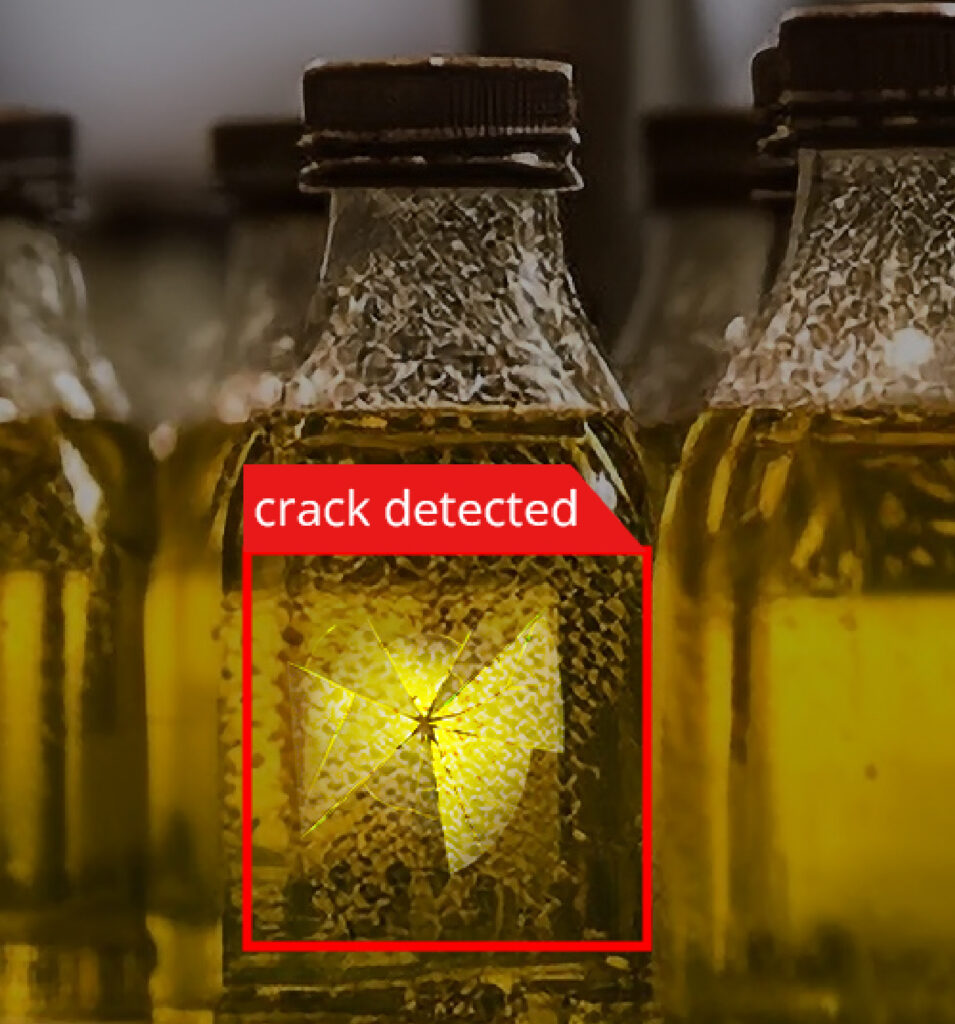

- Package Safety: To maintain food products fresh and contamination-free during storage, transportation, and handling.

- Quality Assurance: To ensure the packed containers and products meet the desired quality level.

- Inaccuracy: Manual checks are both time-consuming and inaccurate.

Avoid Product Contamination and Wastage with our Automated Leak Detection

Monitor your manufacturing process and optimize operations for improved efficiency with detailed analytics and reporting.

- Image Acquisition: Capture images or videos.

- Image Preprocess: A model is trained to detect leaks in pre-processed data.

- Leak Detection: The trained model is deployed and continuously monitors for leaks.

- Alert Generation: Notify operators or maintenance personnel through an alarm.

Optimize your Packaging Process with our Machine Vision leak detection

Leakages in packaging lead to different issues from product spoilage and customer dissatisfaction. Identifying and rectifying these leaks instantly is crucial to maintain the integrity of your products and safeguard your brand. Implement our Leak Detection Algorithm in your manufacturing process and achieve accurate, fast, and efficient detection to prevent product loss and contamination risk.