Package Inspection

Optimizing Packaging Inspection with Vision AI

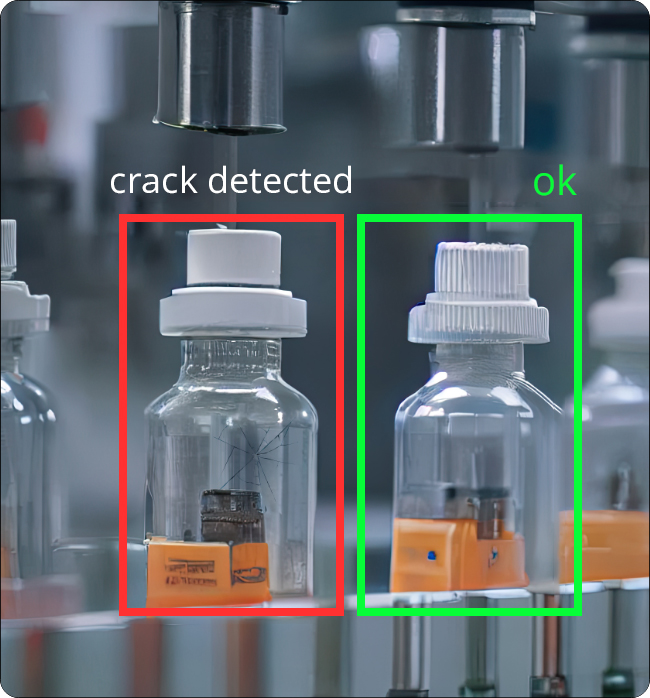

In the pharmaceutical industry, the use of Vision AI algorithms has transformed Package Inspection by enabling the verification of seals, labels, print quality, and container integrity to enhance the quality of the packages. It guarantees precision in tamper evidence, batch consistency, and more, enhancing the effectiveness of quality control measures.

Meeting Packaging Quality Assurance Heads-On with Computer Vision

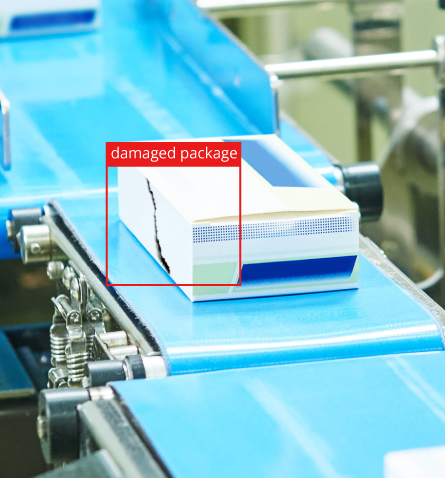

The pharmaceutical sector faces unique challenges in Package Inspection, stemming from diverse packaging defects, rigorous regulatory standards, and the need to adapt to evolving market dynamics.

- Package Diversity: Varied shapes and sizes demand sophisticated inspection techniques to accommodate different product types.

- Print Quality Challenges: Ensuring high print quality is crucial, with issues such as ink smudges, fading, and misprints requiring specialized inspection systems.

- Adapting to Surfaces: Labels applied to curved and irregular surfaces demand flexible detection methods to maintain accuracy.

- Dynamic Production Environments: Consistency in inspection standards across diverse batches and fast-paced production settings present ongoing challenges.

Automating Package Inspection with Vision AI

Our modern approach integrates Vision AI and streamlines methodologies to enhance the precision and efficiency of pharmaceutical Package Inspection.

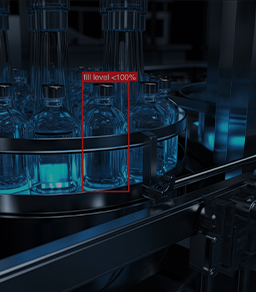

- Image Acquisition: Using advanced cameras and imaging devices to capture high-resolution images for detailed analysis.

- Preprocessing and Segmentation: Employing sophisticated techniques to isolate and enhance specific package regions within images.

- Feature Extraction and Recognition: Leveraging OCR and pattern recognition for accurate identification and verification of critical package information.

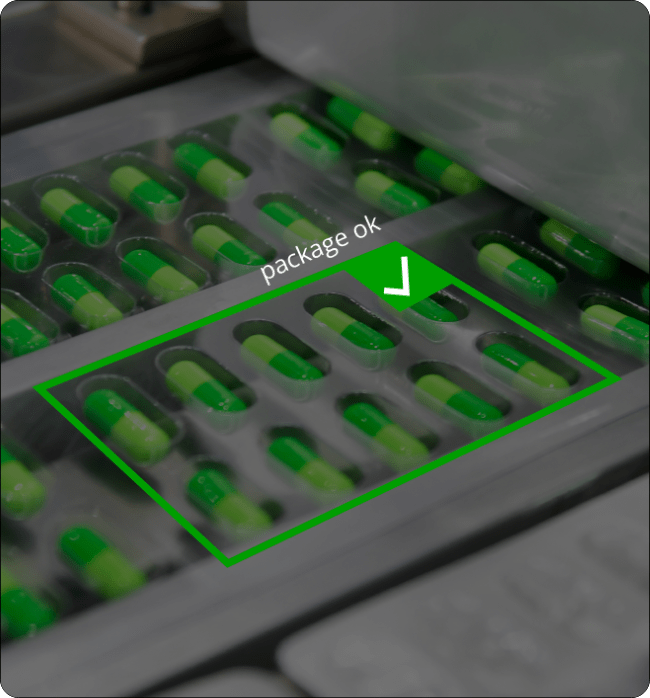

- Defect Detection: Deploying anomaly detection algorithms to pinpoint and address defects or irregularities in package content or print quality.

- Decision Making and Reporting: Using inspection results to inform decisions and generate comprehensive reports on package quality and conformity.

Optimal Packaging Quality Assurance with Vision AI

Using Computer Vision for Package Inspection improves your quality control processes, reduces errors, and ensures compliance with industry regulations.

- Label Alignment and Placement: Guaranteeing precise alignment and placement of labels on pharmaceutical packaging for a polished and standardized appearance.

- Text and Barcode Verification: Rigorously verifying the accuracy, legibility, and compliance of printed text, barcodes, and other information on pharmaceutical packages.

- Printing Quality Assessment: Evaluating label printing quality to identify and address issues such as smudging, fading, or uneven ink distribution for clear and easily readable labels.

- Tamper-evident Features: Implementing thorough inspections of tamper-evident features on pharmaceutical packages to ensure product authenticity and enhance consumer safety.

Amplify Your Packaging Inspection with Vision AI

Our Vision AI solution guarantees the utmost accuracy in every inspection, including seal verification, label scrutiny, print quality checks, and more. Elevate your quality control processes with our innovative approach for unparalleled reliability and performance.