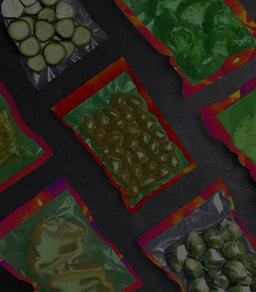

Package Seal Inspection

Prevent Tampering Using Package Seal Inspection with Vision AI

Proper seals extend the life of perishable goods by preventing exposure to air, moisture, or external factors that may degrade the product. By ensuring the seals are intact and reliable, businesses can maintain the freshness, quality, and safety of products. Leverage Vision AI packet seal inspection to quickly and accurately detect packet seal defects to prevent product contamination, tampering, and damage during storage, transportation, or sale.

Navigating Challenges in Package Seal Inspection to Ensure Product Integrity

To prevent manual inspection and implement an automated packet seal inspection that accounts for the specific needs of the production environment.

- Product Contamination: Improper debris can create tiny pathways that allow harmful bacteria to contaminate the product.

- Wastage of Products: Contamination, spoilage, or foreign materials can result in increased production line wastage, which can be costly.

Ensure Package Seal Integrity and Safety with Vision AI

Maintain the quality of products and reduce the defects of spoilage, product recalls, and damage to a brand.

- Scan: Packages move along the production line and are subjected to scanning using advanced imaging technology , high-resolution cameras and sensors that capture detailed images.

- Defect Detection: Deep Learning algorithms detect any defects or anomalies in seals.

- Reports: Reports are generated on the inspection process and performance can be monitored.

Tamper-proof your Products using

Package Seal Inspection with Vision AI

Automate your quality control process and reduce the risk of product defects, increase efficiency, and improve product quality. Maintain product integrity, comply with regulations, build consumer trust, and minimize financial risks associated with compromised packaging.