Vision AI for Meat Fat Rejection Optimization in the Pet Food Industry

- Vathslya Yedidi

- February 5, 2024

Introduction

As technology continues to progress, industries are constantly seeking innovative ways to enhance efficiency, precision, and quality. Vision AI has emerged as a groundbreaking technology for various businesses due to its exceptional ability to analyze images and make informed decisions.

One such industry is the pet food industry, which has seen a significant rise in the demand for delivering high-quality pet food products to customers. Consumers are becoming increasingly concerned about the ingredients and nutritional value of the food they buy for their beloved pets. This has prompted manufacturers in the pet food industry to explore innovative solutions to enhance the quality of their products.

Vision AI has a wide range of applications in the pet food industry. Out of that, one important factor is accurately identifying the fat content in meat pieces during production processes. In pet food meat processing, ensuring high-quality products and meeting the ever-changing demands of pet owners relies heavily on the strict quality standards of pet food products.

Before going further, what exactly is meat fat rejection? Simply put, it identifies and rejects high-fat content according to the company’s standard requirements from production lines during the process. Traditionally, this was done manually by humans. However, the process is now being improved with the help of Computer Vision algorithms.

If Vision AI is used for Quality Control in the process, you can look forward to an even more rigorous and precise fat rejection system, leading to higher-quality meat food products for pets.

In this article, we will delve into the transformative impact of Vision AI on the pet food manufacturing sector, specifically in enhancing the fat rejection process and increasing the quality of ingredients in pet food. Stay tuned to uncover the intricacies of enduring challenges within this procedure.

Challenges of Meat Fat Rejection on Production Lines

If you’re the owner of a pet food processing company, the quality of the ingredients i.e. beef, mutton, and pork that you use for pet food matters. However, the conventional methods for separating fat from meat come with several challenges.

- The process involves physically removing fat from meat by skilled workers

- It is labor-intensive and relies heavily on the worker’s skill level and speed

- Human subjectivity can lead to variability in fat content

- Trust in human judgment results in inconsistencies and errors

- Different workers may interpret fat levels differently

- Fatigue or lack of concentration can cause unintentional inconsistencies

- Differences in worker techniques can lead to significant product variation

- The manual fat rejection process is time-consuming, affecting production efficiency

- Slower production times increase labor costs

- Regular training to maintain accuracy adds to operating expenses

How Vision AI is Analyzing the High-fat Content on Production Lines?

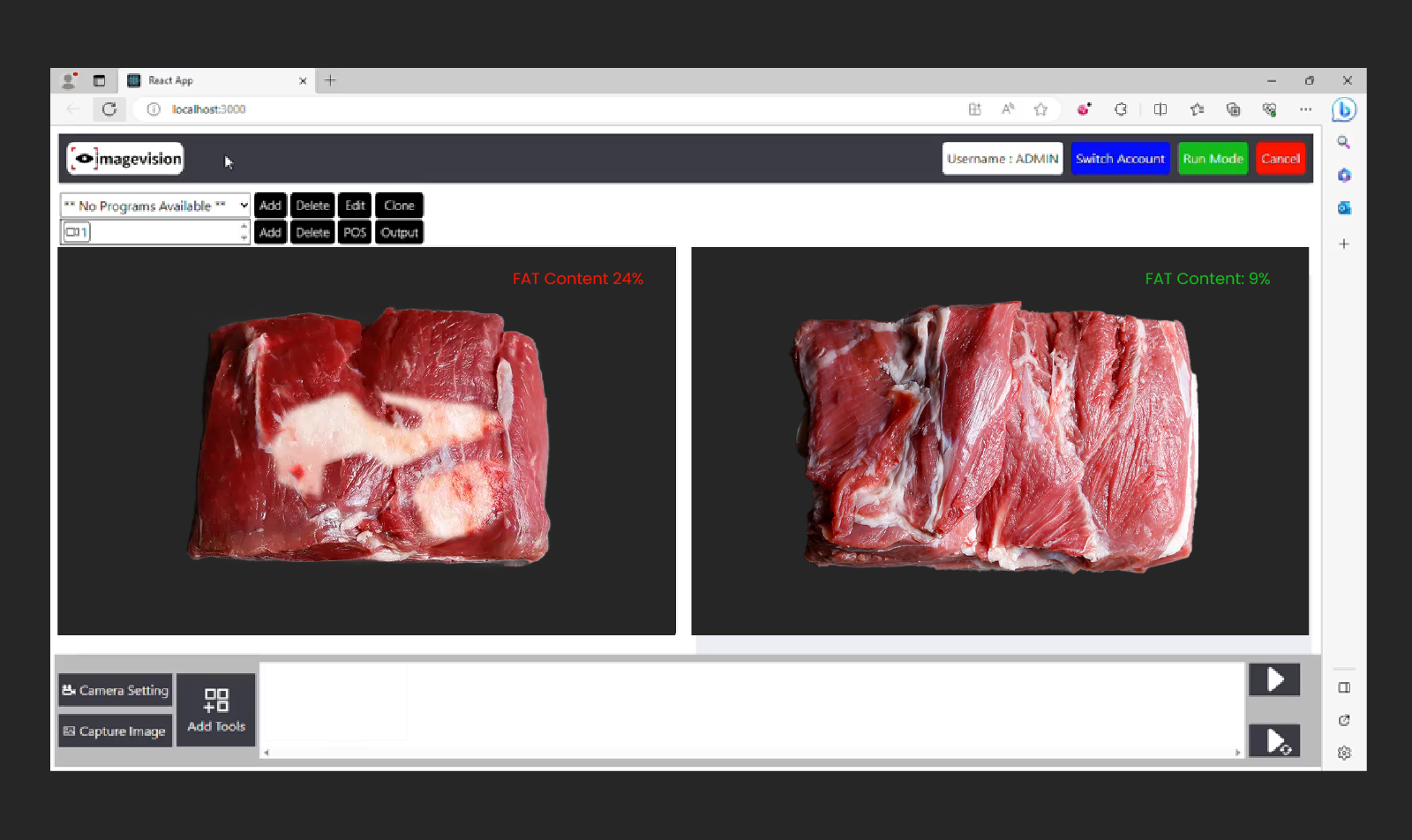

This process aims to operate seamlessly, ensuring the inspection of significant quantities of meat products without causing any disruptions to the workflow. It automates the entire process of quality inspection, which is currently done manually. This will greatly improve efficiency and accuracy in identifying and addressing issues related to fat content and dimensions.

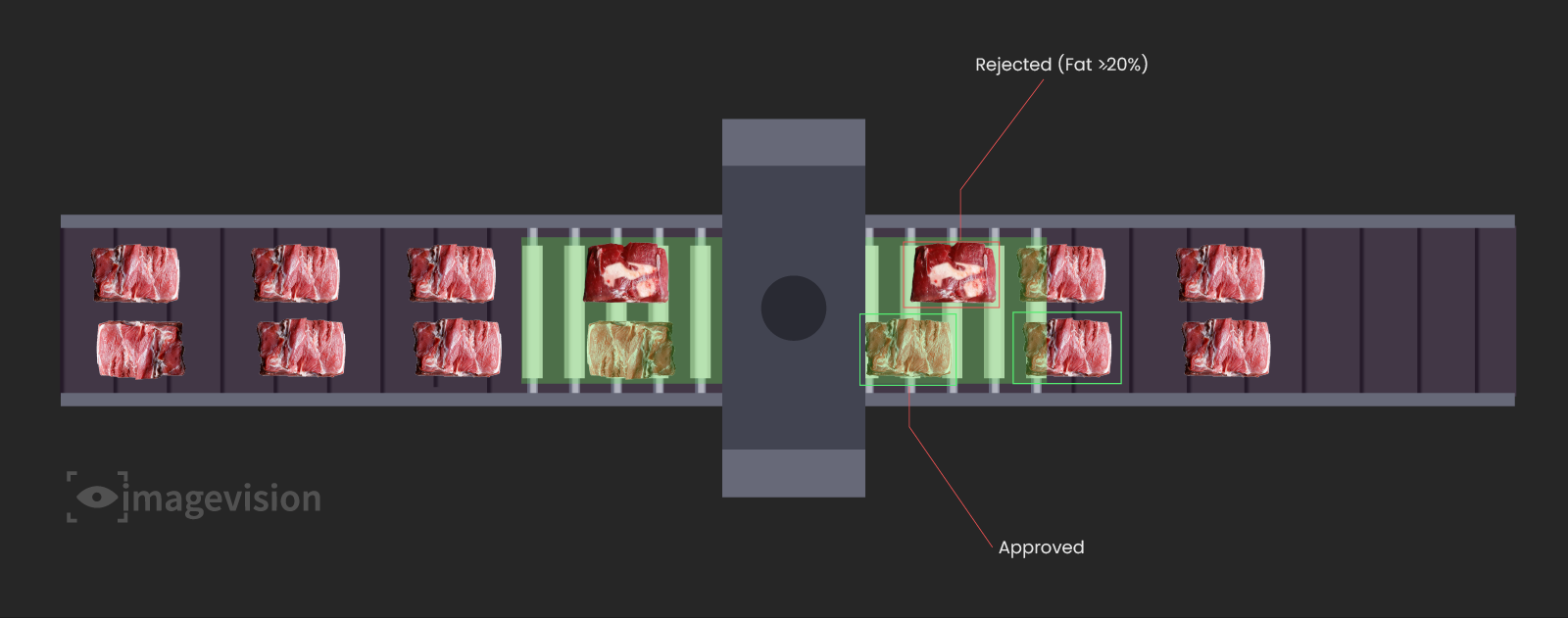

The process will conduct a thorough examination of the upper portion of meat slices to determine the fat content. Any piece of meat that exceeds the predetermined fat threshold, which can be customized to specific requirements, will be categorized as non-acceptable. Subsequently, these non-acceptable pieces will be promptly removed from the production conveyor line.

In addition to inspecting fat content, it can also analyze the dimensions of each meat piece. Any piece with an area below the predefined threshold will be flagged as an anomaly and rejected from the production conveyor line. The threshold value for the area can be adjusted to align with specific requirements, providing flexibility. The final results can be seen in the image below.

Implementing this comprehensive approach to quality inspection changes the entire process, ensuring a more efficient, accurate, and automated solution that enhances overall quality control in meat production.

Case Study: Transforming Fat Rejection Processes in Pet Food Manufacturing Production Lines

Let’s explore a unique scenario that demonstrates Meat Fat Rejection with Vision AI to optimize meat processing procedures in pet food manufacturing.

At a pet food manufacturing company already using Vision AI, a challenge emerged regarding the absence of a process to seamlessly reject high-content fatty meat pieces during the ongoing production of pet food. Without a solution, the company faced setbacks. Here’s how Vision AI played a crucial role:

Identifying the Challenge: Recognizing the need for a smoother process to reject high-fat meat pieces during continuous pet food production.

Strategic Implementation: Vision AI was introduced within the production line to swiftly identify and remove pieces with high-fat content. This inventive approach ensured that non-acceptable pieces were flagged and eliminated without causing interruptions.

Seamless Integration: By strategically embedding the Vision AI solution within the existing pet food production line, the company minimized problems while effectively addressing the crucial issue of fat rejection during the ongoing manufacturing of pet food.

Enhanced Efficiency: The new setup not only improved the overall efficiency of the pet food production line but also maintained a consistent, high-quality pet food product throughout the manufacturing process. This innovative solution showcased Vision AI’s adaptability in addressing specific challenges within the pet food manufacturing industry.

Conclusion

Wrapping it up, using Vision AI in the pet food manufacturing industry reinvents the way that traditional process removes fat, boosting quality control and efficiency. This tech surpasses the constraints of manual work and offers instant data analysis, guaranteeing consistent meat products. We have seen how Vision AI aids in better workflow, saving costs, better customer experience, and maintaining product quality. It’s an innovative solution that paves the way for better meat processing, from automatic detection to detailed analysis.

Ready to optimize your pet food manufacturing processing with Vision AI? Contact us today to upgrade your production lines with Vision AI.