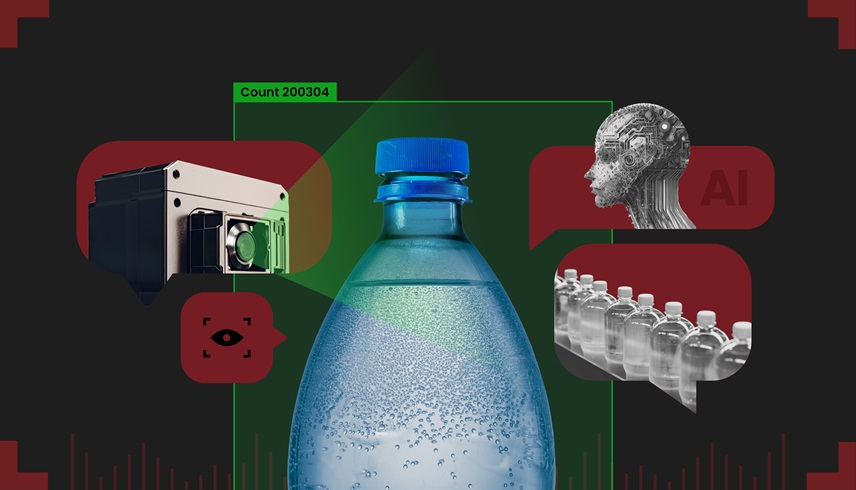

Bottle Inspection by Vision AI: The Bottled Water Industry of the Future

- Vathslya Yedidi

- February 8, 2024

Host: Wanpherlin Shangpliang

Panelist: Greenu Sharma & Rahul Sudeep

Wanpherlin is an integral part of the marketing team at ImageVision.ai, bringing her expertise in strategic marketing management to the forefront. In this discussion, Wanpherlin will be engaging with Rahul and Greenu to explore the impact of Vision AI technology in the bottled water industry, providing insights into the challenges, solutions, and future prospects from a marketing perspective.

Wanpherlin

Rahul is the Marketing Director at ImageVision.ai. In his role, Rahul is responsible for shaping the marketing strategies of ImageVision.ai's products and services. With a background likely rooted in marketing and technology, he plays a crucial role in communicating the benefits and innovations of ImageVision.ai's Vision AI technology to potential clients and the broader market. His expertise lies in understanding market trends, consumer needs, and the competitive landscape, which he leverages to position ImageVision.ai as a leader in Vision AI solutions.

Wanpherlin

Greenu, on the other hand, is the Vice President of Innovation at ImageVision.ai. His role involves spearheading the development and implementation of Vision AI technologies within the company. With a strong background in technology and innovation, Greenu likely leads the research and development team, focusing on creating advanced Vision AI solutions that address the challenges in the bottled water industry. His expertise is crucial in driving the technological advancements of ImageVision.ai's products, ensuring they are not only cutting-edge but also effectively meet the evolving needs of the industry. Together, Rahul and Greenu represent the dynamic synergy between marketing and innovation at ImageVision.ai, working to bring transformative Vision AI solutions to the bottled water industry.

Wanpherlin

Welcome, Rahul and Greenu. We’re excited to discuss how Vision AI is revolutionizing quality control in the bottled water industry. Rahul, as ImageVision.ai's Marketing Director, could you describe the current challenges in quality inspection in this sector?

Rahul

Thank you for having us. The industry is currently at a crossroads. Traditional methods, predominantly manual, are proving inadequate in the face of modern production demands. They lack the speed and accuracy required for high-volume production, leading to inefficiencies, increased waste, and even potential health risks due to undetected contamination or leaks.

Greenu

To add to Rahul’s point, the industry is not just dealing with the inefficiency of manual inspections but also with their inherent limitations. Human inspectors, despite their best efforts, might miss subtle defects due to the sheer speed and volume of the production line. This becomes a significant issue when you consider the implications of these defects – from consumer safety to legal compliance.

Wanpherlin

Those are substantial challenges. Greenu, could you elaborate on the specific problems these industries face with existing quality inspection methods?

Greenu

Certainly. One of the biggest challenges is detecting micro leaks in bottles. These tiny leaks can lead to major product recalls, damaging the brand's reputation and incurring substantial financial losses. Additionally, ensuring the integrity of caps and the accuracy of labels at high production speeds is a real challenge. Any error here can lead to serious safety concerns and regulatory non-compliance. Furthermore, these manual methods are resource-intensive, leading to higher operational costs.

Wanpherlin

It sounds like a complex problem. Rahul, how is Vision AI technology providing solutions to these challenges?

Rahul

Vision AI is a transformative solution. Our ImageVision Solutions, for instance, employ state-of-the-art cameras and deep learning algorithms that can conduct thorough inspections at unparalleled speeds. These systems are capable of inspecting several thousand bottles per minute, detecting leaks, assessing cap integrity, and verifying label information with impressive accuracy. The AI continuously learns from the inspection process, enhancing its detection capabilities over time. This significantly reduces the margin of error and increases overall production efficiency.

Greenu

And let’s not forget the adaptability of Vision AI. We’ve successfully implemented these solutions across different types of bottles, including glass. Glass presents unique challenges due to its transparency and the variety of shapes and designs. Our AI algorithms are specifically trained to handle these intricacies, detecting a wide range of defects that might be invisible to the naked eye.

Wanpherlin

That’s remarkable. Can you both speak a bit about the future developments you anticipate for Vision AI in this industry?

Rahul

Looking ahead, the integration of Vision AI with other emerging technologies, such as the Internet of Things (IoT), holds immense potential. This integration will enable more comprehensive monitoring and control over the entire production process. As these AI models continue to evolve, they will become more adept at identifying even the most subtle defects, making them an indispensable part of quality control in the bottling industry.

Greenu

Indeed, the future is about holistic transformation. Vision AI is set to expand its role beyond mere defect detection. Imagine a fully automated production line, from raw material inspection to final packaging, all overseen by intelligent AI systems. This would not only optimize production efficiency but also ensure the highest standards of product quality. The implications for this are vast – reduced operational costs, increased productivity, enhanced product safety, and a significant boost to brand reputation.

Wanpherlin

This conversation has been incredibly enlightening. Thank you, Rahul and Greenu, for sharing your insights into how Vision AI, particularly ImageVision Solutions, is poised to redefine quality control in the bottled water industry.

For a detailed consultation and to discover how Vision AI can transform your bottling operations, Contact us today. Let’s harness the potential of Vision AI to ensure your business not only keeps pace but sets the benchmark in production excellence.