Seeing is Believing: How Computer Vision is Revolutionizing FMCG Control Lines

- Wanpherlin M Shangpliang

- August 22, 2023

Demonstration:

Welcome to the exciting world of Computer Vision, where machine eyes transform FMCG (Fast Moving Consumer Goods) inspection lines into powerhouses of efficiency and precision. Imagine this: a symphony of conveyor belts, sensors and AI-controlled cameras working in harmony to ensure that the products you buy are of the highest quality. In this blog, we explore how Computer Vision is changing inspection processes in the FMCG industry and look into the crystal ball to see the future of this exciting technology.

Machine Eye: Computer Vision in FMCG Inspection:

Just like a hawk searching high for its prey, Computer Vision has become the sharpest eye for FMCG manufacturers. Gone are the days of manual inspection where human error and fatigue could lead to carelessness. With the help of Computer Vision, every product through the inspection line is carefully inspected and checked against predefined quality parameters.

Cameras supported by powerful algorithms detect even the smallest errors and ensure that only products that meet strict quality standards reach the market. Computer Vision is a guardian angel that protects the integrity of your favourite products.

Peeling back the layers: How does computer vision work?

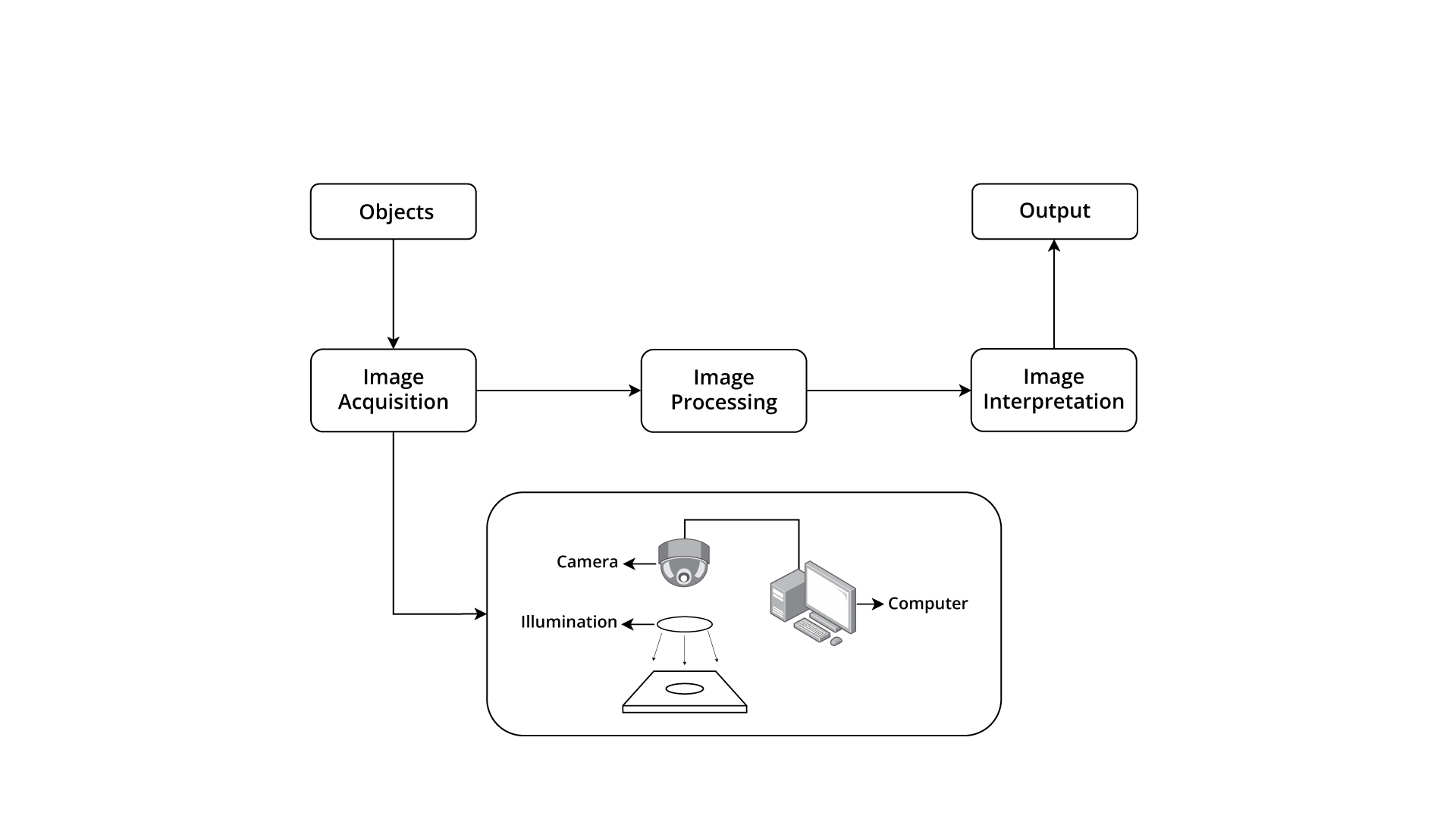

Behind the curtain of this technological wonder is a complex process that combines image processing, machine learning and pattern recognition. Cameras photograph products at various stages of the inspection line. These images are then processed through neural networks where patterns and anomalies are detected and compared with the desired parameters. Algorithms are constantly learning and adapting, becoming smarter and more efficient with each check. It’s like having an army of Sherlock Holmes at your service, making sure no mystery goes unsolved on the production line.

Advantages of Computer Vision in FMCG:

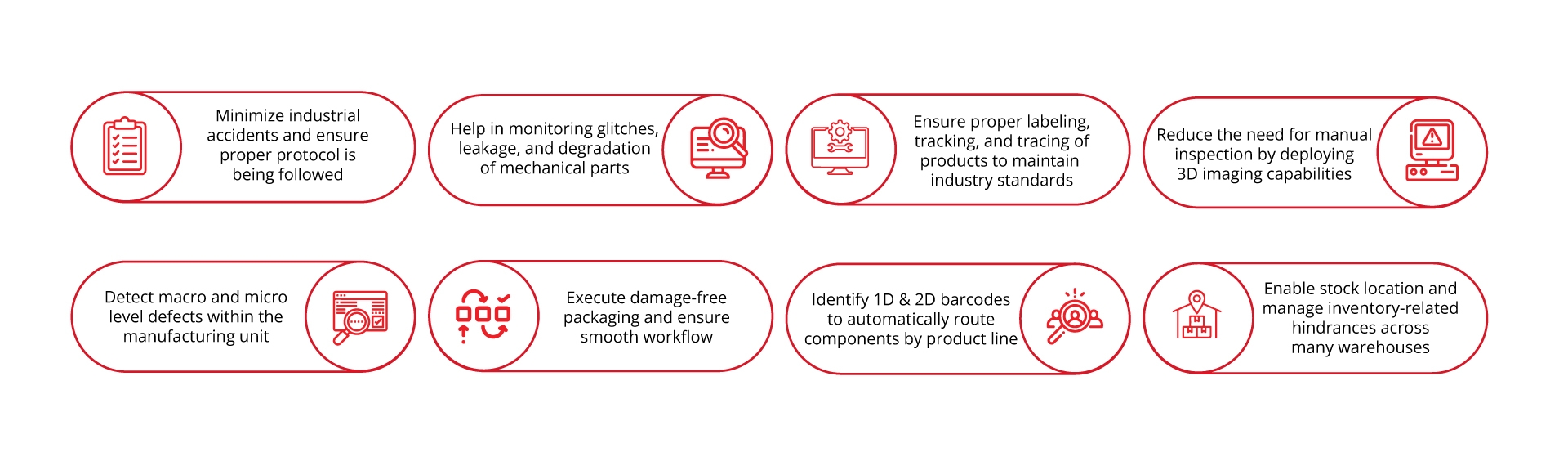

Speed and accuracy are Computer Vision’s superpowers, but that’s not all it brings to the table. FMCG industries have seen several new benefits since adopting this technology:

Advanced quality control: Computer Vision leaves no room for error, minimizing product defects and recalls.

Increased productivity: Automating inspections increases production speed and ensures a consistent flow of goods to meet consumer needs.

Data-driven insights: By analysing data collected during inspections, manufacturers gain valuable information about production processes, leading to continuous improvement.

Cost Effectiveness: While investing in Computer Vision technology may seem daunting, the long-term cost savings from reduced waste and rework justify the initial investment.

Brand Image: As consumers seek higher quality products, brand image increases, which increases customer loyalty and trust.

Looking ahead: What’s on the horizon for computer vision in FMCG? The journey of Computer Vision in the FMCG industry has just begun. As technology progresses, we can expect even more significant advancements.

Real-time analytics: Imagine an artificial intelligence system that can instantly analyse production data and predict potential defects before they occur, preventing defective products from leaving the market.

Focus on Sustainability: Computer Vision could expand its ability to identify environmentally friendly packaging and ensure sustainable practices, furthering the industry’s commitment to environmental responsibility.

Seamless integration with IoT: Integration with the Internet of Things (IoT) enables even deeper monitoring and control of the entire production process, creating a fully connected smart factory.

3D imaging and more: With 3D imaging technology, Computer Vision was able to inspect products from all angles, providing a holistic view of quality and revealing hidden defects. Robotic Handling and Sorting: Computer Vision-equipped collaborative robots could independently sort and handle products together with humans.

Conclusion:

As we say goodbye to the traditional magnifying glass and enter the era of computer vision for FMCG inspection lines, we are witnessing a fundamental shift in the industry. A powerful combination of automation, accuracy and data insights has transformed quality control into an art form. And as technology continues to advance, the future holds exciting promises for the FMCG industry where products are not only controlled but also manufactured to perfection.

So, the next time you pick up your favourite snack at the store, remember that behind that flawless exterior are the watchful eyes of Computer Vision, making sure you’re getting only the best. Happy nibbling!