Packaging and Label Inspection with Computer Vision for 5-Gallon Bottled Water

- Wanpherlin M Shangpliang

- July 18, 2024

As a bottled water producer, are you confident in the quality of every 5-gallon bottle leaving your facility? In an industry where consumer trust is vital, even minor faults can lead to significant consequences, including safety risks, product recalls, and damage to brand reputation.

Bottled water is a daily necessity for millions, delivered to homes, offices, and businesses. However, as the demand for bottled water grows, maintaining flawless quality standards requires innovative solutions.

Bottle packaging and label inspection with Computer Vision is the most effective way to ensure bottle quality. This solution automates the detection of defects, inconsistencies, and contaminants, enabling producers to maintain high standards while optimizing efficiency. Integrating these systems, companies can safeguard their operations, enhance consumer trust, and meet growing market demands.

This blog explores bottle packaging and label inspection with Computer Vision to ensure every bottle’s safety, compliance, and consistency.

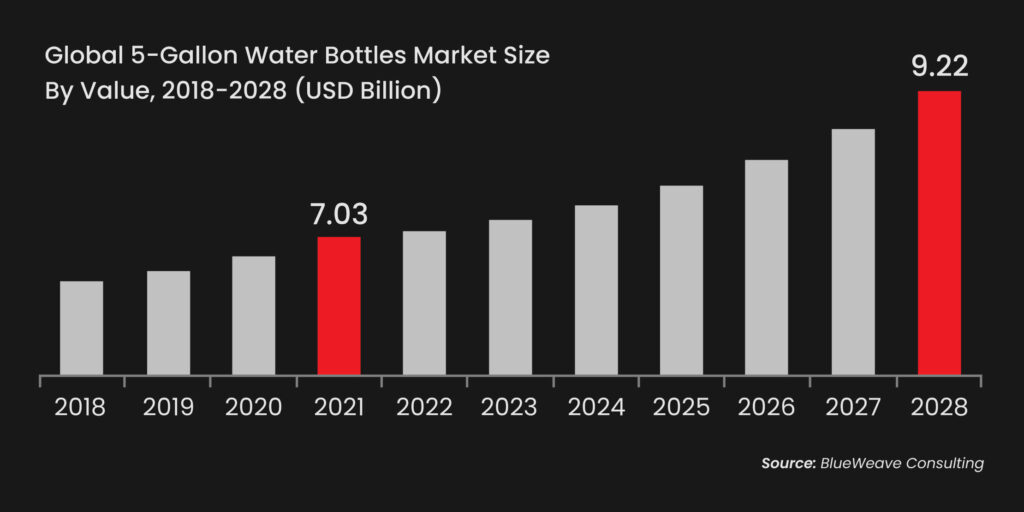

Global Market for 5-gallon Bottled Water

The global market for 5-gallon bottled water is expanding. Valued at $7.03 billion in 2021, it is projected to reach $9.22 billion by 2028, growing at a CAGR of 4.1%, according to Blue Weave Consulting. This growth highlights the increasing demand for bottled water. It underscores bottle inspection’s importance for quality in maintaining customer satisfaction, regulatory compliance, and industry competitiveness.

Recent Recalls Highlight the Importance of Quality Control

Product Recalls: In January 2024, the US Food & Drug Administration reported 30 product recalls. Of these, 21 involved food and beverage products, 2 were related to pet products, and 7 pertained to drugs or medical devices.

Foreign Particles in Bottles: In November 2023, over 3,800 Waiākea Hawaiian Volcanic Water cases were recalled after customers reported “floating particles” in the water.

Why Bottle Packaging and Label Inspection with Computer Vision Matters in 5-Gallon Water Production?

Any quality lapse, from contaminated water to mislabeled bottles, can have long-lasting consequences for a company’s reputation and profitability. Let’s see why it is important

- Consumer Safety: As many people’s primary drinking water source, any quality compromise can directly impact consumer health.

- Brand Reputation: Quality inconsistencies can devastate consumer trust and brand loyalty in the bottled water market.

- Regulatory Compliance: Strict industry standards require meticulous attention to detail in packaging and labeling.

- Economic Impact: Quality-related recalls can be financially crippling, affecting not just profits but also market position.

Key Challenges in 5-Gallon Bottled Water Quality Control

Ensuring quality in 5-gallon bottled water production presents unique inspection challenges due to the bottle’s size, shape, and material. These challenges include:

1. Large Surface Areas:

The extensive surface of 5-gallon bottles makes identifying small defects like scratches, cracks, or imperfections difficult. This can impact the accuracy of bottle inspection processes, potentially allowing defective products to pass undetected.

2. Varied Lighting Conditions:

Reflections, shadows, and uneven lighting on the bottle’s curved surfaces can interfere with inspection accuracy. This poses significant challenges in maintaining consistency during bottle inspection, especially in high-speed environments.

3. Transparency and Refraction Issues:

The transparent material of 5-gallon bottles creates refraction and glare, making it harder to detect internal or surface defects. Such challenges can hinder effective Bottle Defect Detection, increasing the risk of unnoticed flaws.

4. High-Speed Production Lines:

High-speed bottling lines reduce the time available for inspections. Detecting issues like label misalignment or missing information becomes challenging, particularly when conducting label quality Inspection on a scale.

5. Handling and Durability Testing:

Reusable 5-gallon bottles experience wear and tear from repeated use. Cracks or weak spots caused by handling overtime present a persistent challenge in maintaining quality.

6. Internal Contaminant Detection:

Due to the size and transparency of large bottles, detecting foreign particles, sediments, or residues inside them is challenging. However, this issue remains critical to Bottle Inspection processes to ensure consumer safety.

What is the Role of Computer Vision in Packaging and Label Inspection?

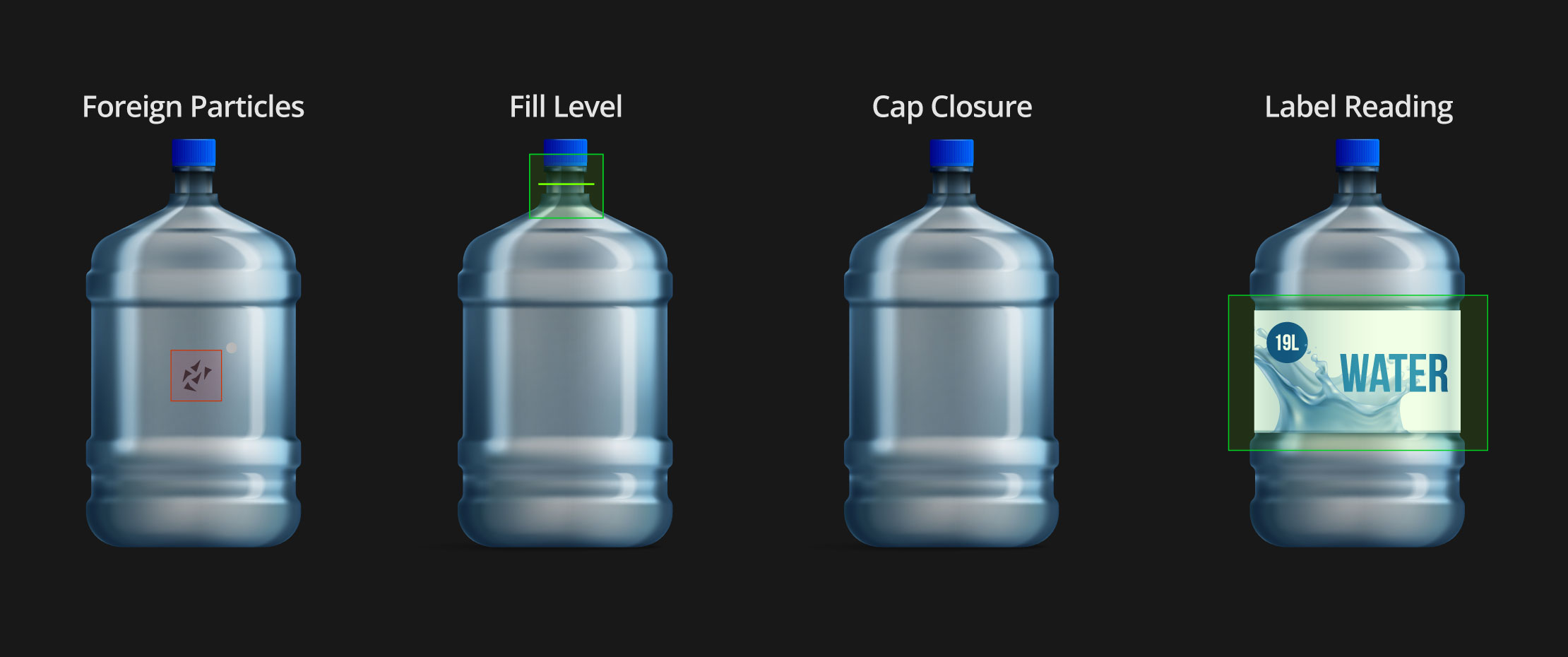

Bottle inspection with Computer Vision is changing quality control in the bottled water industry. Here’s how it addresses key areas.

Packaging Inspection Features

- Structural Integrity Detection: Detects weak seams, base deformities, uneven neck finishes, and improper molding that can cause leaks, instability, or sealing issues in 5-gallon water bottles.

- Cap Inspection: Identifies improperly sealed or misaligned caps, preventing contamination and maintaining water purity.

- Seal Verification: Confirms that seals are intact and leak-free, ensuring water quality is preserved throughout storage and delivery.

- Surface Defect Detection: Detects foreign particles, residues, or stains on bottle surfaces, maintaining cleanliness and preventing potential health risks.

Label Inspection Features

- Label Presence and Position: Ensures labels are accurately placed and aligned, a critical part of 5-gallon bottled water label quality Inspection to avoid miscommunication with consumers.

- Text Legibility: Verifies that all text, including brand names, instructions, and regulatory information, is clear and readable.

- Barcode Quality: Checks for barcode presence and scans are essential for inventory management and traceability.

- Label Defect Detection: Identifies issues such as tears, wrinkles, or bubbles in labels, which could compromise branding or violate 5-gallon Bottled Water Label Packaging Quality Control standards.

- Date Code and Batch Number Verification: Confirms the presence and accuracy of printed date codes and batch numbers to meet regulatory compliance and enable product traceability.

Real-World Applications of Computer Vision in the Bottling Industry

Computer Vision significantly benefits the bottled water industry, where quality control is paramount. Below are real-world examples of its applications:

1. Contamination Prevention in Large-Volume Bottled Water

A major supply company implemented bottle inspection systems for 5-gallon bottles to detect microscopic cracks and faulty seals. These systems identified potential contamination risks early, preventing illness among consumers and avoiding costly recalls.

2. Ensuring Brand Consistency for a Premium Water Service

A premium water delivery service uses Computer Vision for 5-gallon bottled water label quality inspection. It identified subtle label defects like color inconsistencies and micro-tears, reducing customer complaints and strengthening brand loyalty.

3. Optimizing Production Efficiency in a Multi-Brand Facility

A contract bottling plant implemented a real-time bottle defect detection system on its production line. The company reduced waste and increased production speed across multiple brands by quickly identifying recurring defects.

4. Adapting to Eco-Friendly Packaging Trends

A bottled water company transitioning to sustainable materials employed Computer Vision for packaging and label inspection. The system detected variations in material transparency and cracks, ensuring consistent quality while supporting the brand’s eco-friendly goals.

5. Perfecting Cap Seals for Quality Assurance

A water supplier specializing in self-service refills implemented Computer Vision for cap seal verification. This reduced leak-related complaints and improved customer retention, setting a new benchmark for 5-gallon bottled water quality control.

6. Precision Fill-Level Control for Operational Excellence

A major water delivery service used Computer Vision to monitor fill levels in 5-gallon bottles. The system detected volume discrepancies, minimized waste, and ensured consistent quality, establishing new standards for operational precision.

Conclusion

Adopting Computer Vision is no longer optional but essential for bottled water companies aiming to stay competitive. This approach enables seamless Bottle Inspection, guarantees compliance with stringent regulations, and solidifies consumer trust. Producers can use Artificial Intelligence, Machine Learning, and Deep Learning to perform detailed analyses, detect defects with pinpoint accuracy, and make informed operational decisions.

Ready to elevate your bottled water quality? Let’s discuss how Computer Vision can transform your operations and set new benchmarks for excellence.