Bottling

Automate Bottle Inspection

with Vision AI

Prevent substandard products from reaching the market, avoid product recalls,

and gain customer trust through seamless bottle inspection systems

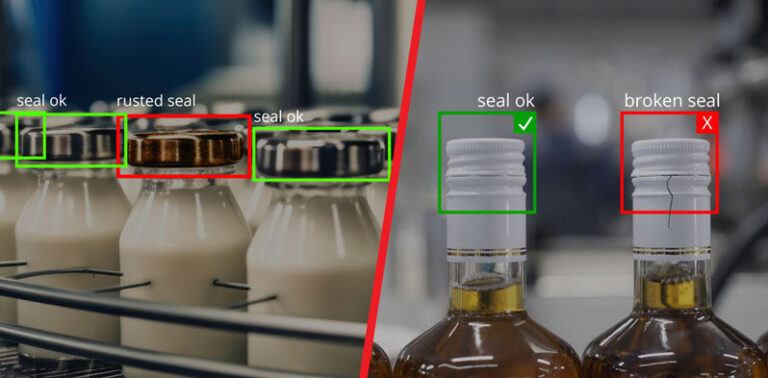

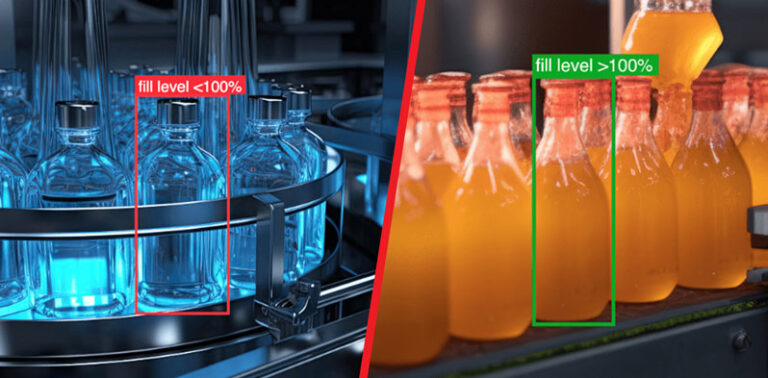

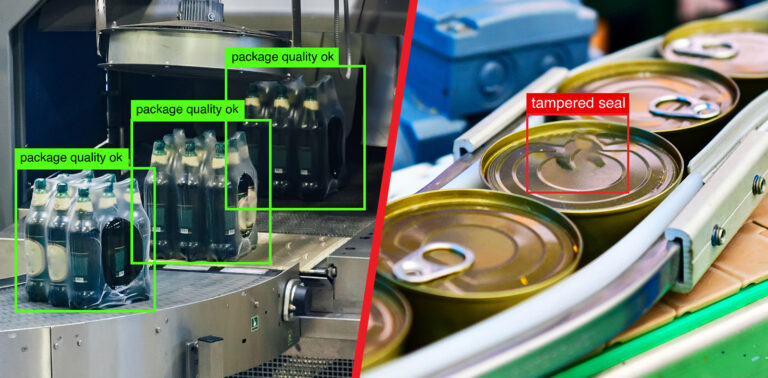

Bottling Inspection with Computer Vision

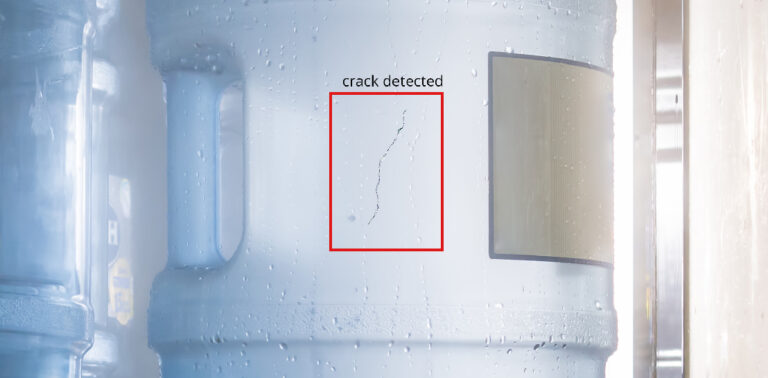

From identifying defects and inconsistencies to measuring dimensions and verifying labels, Computer Vision revolutionizes quality control in the bottling industry, enabling high-speed and accurate inspections, standardization of quality standards, improved defect detection, and real-time data analysis.

Visualize, Analyze, and Automate Bottle Defect Detection with Vision AI

Our algorithm analyzes vast amounts of data, providing real-time insights into production trends, performance metrics, and quality indicators.

Optimize Bottle Quality Control with Vision AI, Reducing Manual Inspection

Vision AI will disrupt bottle quality control, efficiently detecting imperfections and reducing manual inspections. This enhances product consistency and streamlines manufacturing while minimizing human error.

Enhanced Quality Control

Accurate and consistent quality control by automating inspection processes.

Increased Efficiency

Operate at high speeds, exceeding the capabilities of manual inspections.

Early Detection of Defects

Detect and reject bottles with defects in real-time.