Warehouse Management with Computer Vision for Better Inventory Control

- Vathslya Yedidi

- March 4, 2025

Efficient stack management is a fundamental aspect of warehouse operations, yet it remains one of the most challenging areas to optimize. As storage densities increase and fulfillment cycles shorten, businesses must ensure that inventory is stacked, tracked, and retrieved with precision. Traditional approaches relying on barcode scanning, RFID systems, and manual audits are struggling to keep pace with the scale and speed required in modern supply chains.

The introduction of Computer Vision and autonomous drones for stack management in warehouses presents an opportunity to enhance stack visibility, streamline inventory tracking, and reduce inefficiencies caused by missed, misplaced, unstable, or unaccounted-for stock. By integrating warehouse management with Computer Vision powered monitoring and real-time data collection, businesses can transition from reactive inventory management to a proactive, self-optimizing warehouse ecosystem.

The Hidden Costs of Poor Stack Management in Warehousing

Warehouse operators often face persistent challenges in stack management due to limited real-time visibility, manual counting errors, and the inability to assess storage stability dynamically. These inefficiencies have compounding effects on operations, impacting inventory accuracy, warehouse safety, and productivity.

One of the most critical issues is product instability during lifting and retrieval. As forklifts or automated storage and retrieval systems (AS/RS) lift pallets to high racks, products may shift, leading to stack imbalances or, in some cases, inventory falls. Not only does this contribute to product damage and financial losses, but it also poses operational risks that compromise warehouse safety standards.

Additionally, inspecting stock stored at higher levels introduces further complications. If a product needs verification or physical inspection, retrieving it often requires moving multiple other items, increasing the likelihood of misplacement or product loss. The absence of real-time validation mechanisms means inventory blind spots persist, making stock reconciliation time-consuming and resource-intensive.

Inventory misplacement is another major challenge. Products are frequently misplaced due to human error or poor labeling systems. This creates blind spots in inventory tracking, leading to stockouts, overstocking, and delayed order fulfillment. Without real-time location tracking, finding misplaced items adds unnecessary delays and operational inefficiencies.

Inefficient space allocation further compounds these issues. Warehouses often struggle with suboptimal space utilization, as items are stacked without considering future retrieval needs. This leads to congestion, wasted vertical or horizontal space, and increased labor costs for unnecessary rearrangements. Poor visibility into available storage areas results in inefficient use of warehouse capacity, limiting operational efficiency.

A Computer Vision-Driven Approach to Stack Management in Warehouses

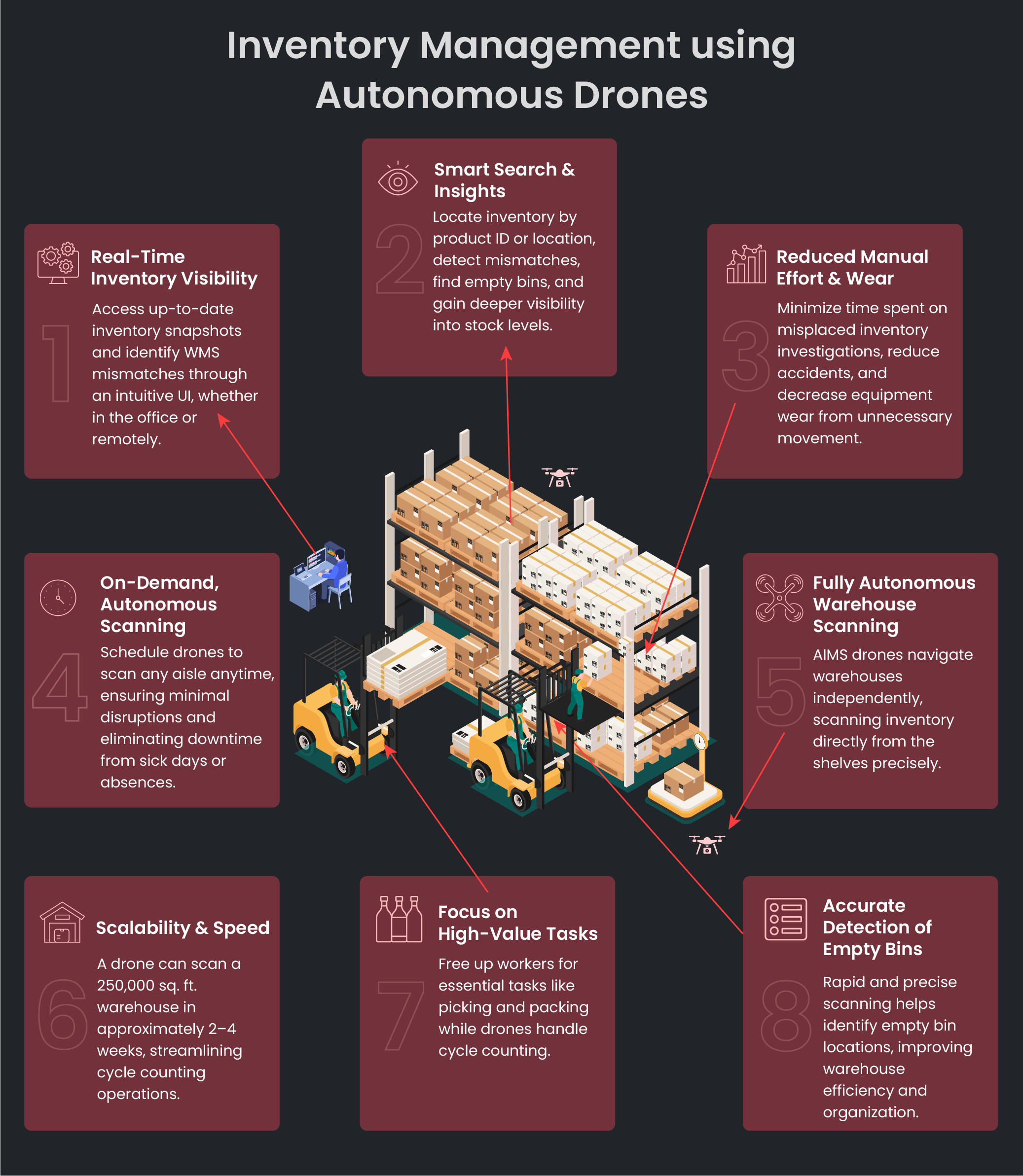

Inventory Management with Computer Vision and autonomous drones enables warehouses to dynamically manage stacks, reducing reliance on manual interventions and addressing key challenges such as stack instability, inventory misplacement, and inefficient space utilization. These approaches improve warehouse safety, accuracy, and operational efficiency by continuously monitoring and validating every movement, placement, and retrieval with Vision AI-driven precision.

1. AI-Powered Stack Assessment for Stability and Optimization

Fixed-position cameras powered by Computer Vision algorithms continuously monitor storage racks, ensuring real-time detection of misaligned stacks, weight imbalances, and inefficient space usage. Unlike manual inspections, AI-driven monitoring provides accurate, consistent, and data-backed insights into stack stability, inventory positioning, and load distribution.

How It Works

- Stack Alignment Detection: AI analyzes pallet positioning and identifies leaning, tilting, or unstable stacks before they become risks.

- Load Distribution Analysis: Vision AI assesses weight imbalances, ensuring even weight distribution to prevent collapses.

- Dynamic Monitoring During Retrieval: The system tracks stack movements during forklift or AS/RS operations, sending alerts if instability is detected before retrieval.

- Optimized Space Utilization: AI identifies underutilized vertical and horizontal space, helping warehouses maximize storage capacity and reduce congestion.

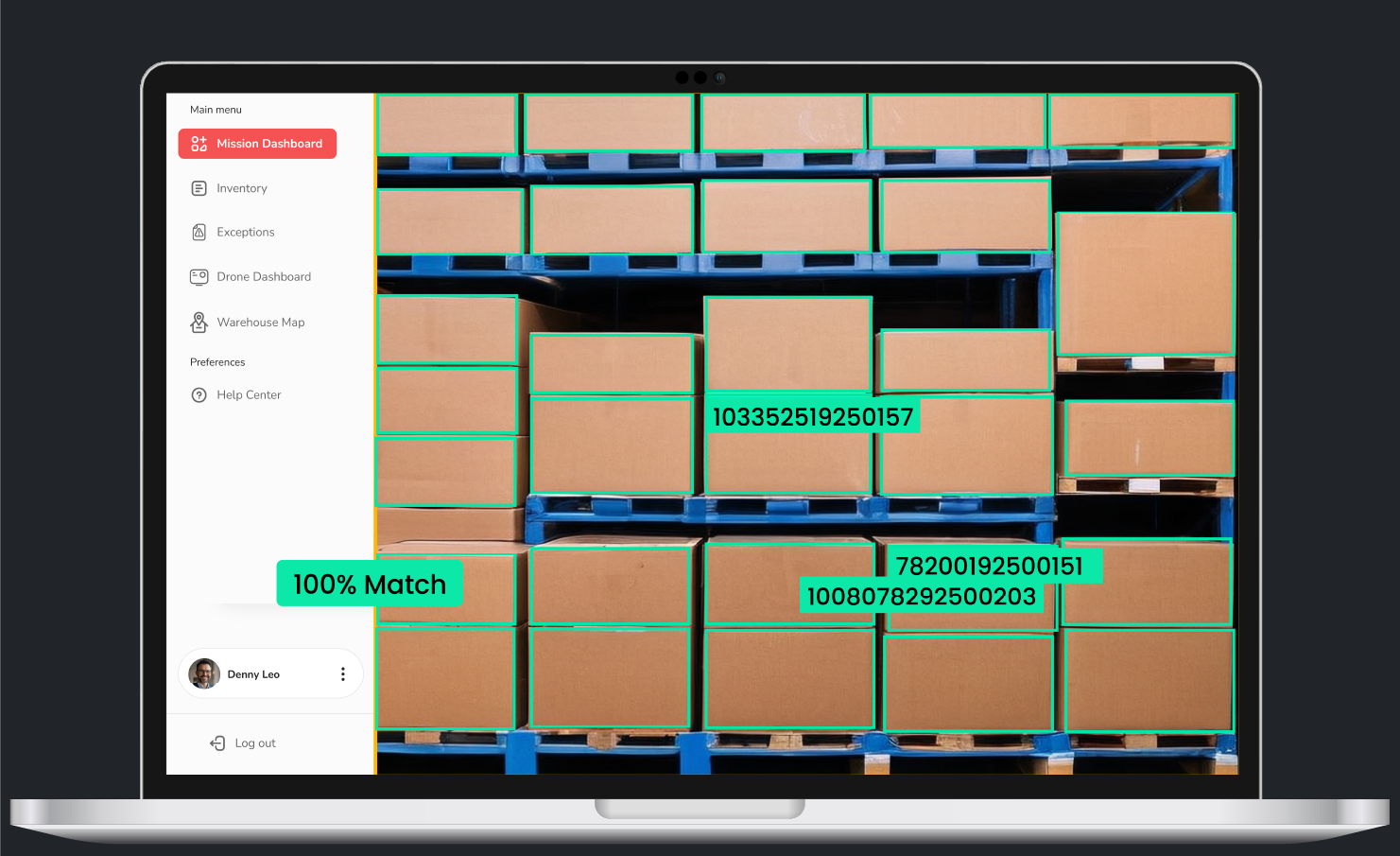

2. Autonomous Drones for Inventory Accuracy and Misplacement Detection

Traditional inventory tracking methods, such as barcode scanning and RFID, require manual intervention and leave blind spots in inventory visibility. Autonomous drones equipped with Computer Vision provide a dynamic, scalable approach to stack monitoring, enabling real-time inventory validation across multiple rack levels without human oversight.

Key Capabilities

- Misplacement Detection: AI-powered item recognition ensures products are stored in the correct locations, reducing stockouts and misplaced inventory.

- Barcode Scanning & Product Verification: Drones scan product labels and cross-check against WMS records to eliminate manual counting errors.

- Tracking Stock Movements: Real-time monitoring of product movements ensures accurate inventory tracking without requiring manual reconciliation.

- Detecting Missing, Fallen, or Damaged Products: AI-driven anomaly detection flags misplaced, fallen, or damaged inventory before they cause operational disruptions.

Impact of Computer Vision on Warehouse Productivity

1. AI-Driven Inventory Tracking

- Stock Accuracy Improvement: Warehouse Management Systems with AI have improved forecasting, reducing errors by 20-50% and enhancing inventory accuracy.

- Cost Reduction: Companies using AI for inventory management have reported up to a 25% reduction in inventory costs.

2. Integration of Computer Vision and Autonomous Drones

- Reduction in Inventory Counting Time: Implementing stock counting using Vision AI and autonomous drones has led to a 75% decrease in inventory counting time.

- Decrease in Misplaced Inventory: Facilities deploying drone-powered inventory monitoring have experienced a 66% reduction in misplaced inventory errors.

Scaling Computer Vision and Drone-Based Stack Management

Integrating warehouse management with Computer Vision and autonomous drones requires a strategic deployment approach for large-scale warehouses. The first step involves deploying AI-driven cameras at key operational touchpoints, including high-density storage areas, retrieval zones, and fulfillment centers. In inventory management with Computer Vision, cameras continuously monitor stack health, identifying irregularities before they cause operational disruptions.

Autonomous drones further complement these efforts by conducting cycle counts, verifying barcode labels, and monitoring high-rack inventory placements. With direct integration into Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) platforms, these AI-driven insights translate into real-time stock updates, predictive maintenance of storage configurations, and improved operational forecasting.

Conclusion: A Vision-Driven Future for Stack Management

The evolution of stack management in warehouses from a reactive, labor-intensive process to a fully automated, AI-driven system redefines warehouse efficiency. Businesses can leverage Computer Vision and autonomous drones to achieve higher inventory accuracy, reduce stock losses, and enhance storage optimization while minimizing disruptions to existing workflows.

With global investments in warehouse automation expected to exceed $41 billion by 2027, companies that integrate AI-driven stack management solutions today will be positioned at the forefront of supply chain transformation. The future of warehouse logistics will not be defined by how much inventory is stored but by how efficiently it is managed, tracked, and retrieved in real-time.

Want to optimize warehouse management? Get in touch with us to explore how Computer Vision and Drones can help.