The Power of Real-Time Monitoring: How Video Analytics is Enhancing Packaging Operations

- Rahul Sudeep

- September 14, 2023

Real-time monitoring has become an indispensable element of modern business environments, particularly packaging operations that rely heavily on video analytics for process optimization, productivity improvements and overall efficiency gains. Here, we explore how real-time monitoring and video analytics are transforming this sector of industry.

1. An Introduction to Real-Time Monitoring in Packaging Operations

Real-time monitoring involves collecting information at multiple stages during the filling, sealing, labeling, and packaging processes. All this is done to detect issues quickly, leading to increased efficiency and cost reductions for businesses and customers alike.

2. Real-Time Data in Packaging Operations

Real-time data is of immense value in the packaging industry as it provides insight into its operations. By monitoring key metrics like production rates, quality control standards and equipment downtime levels, businesses can make informed decisions to optimize their processes and streamline production lines. It also facilitates proactive maintenance to minimize equipment failure risk while reducing downtime significantly.

3. Enhancing Quality Control with Video Analytics

Video analytics plays an essential role in the real-time monitoring of packaging operations. By employing advanced camera systems and machine learning algorithms, businesses can analyze video footage in real-time to spot defects, inconsistencies or anomalies within the packaging process and take immediate corrective actions to ensure only high-quality products reach the market.

4. Optimizing Productivity and Efficiency

Real-time monitoring allows businesses to quickly identify bottlenecks and inefficiencies within their packaging processes, and reallocating resources or shifting production schedules as soon as discrepancies arise, leading to higher productivity, decreased waste production and overall greater efficiency.

5. Avoid Equipment Downtime with Predictive Maintenance

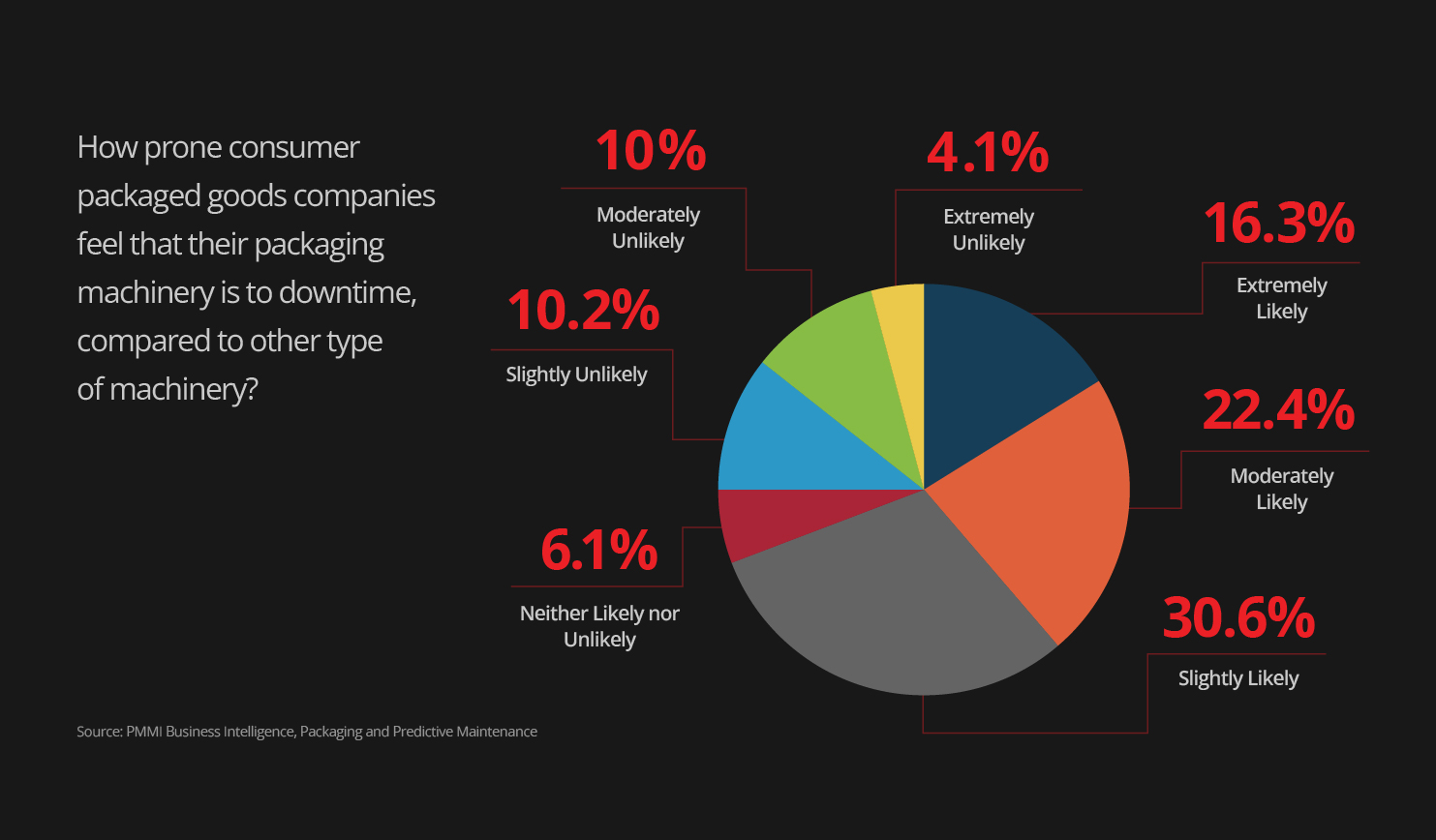

Real-time monitoring offers one key benefit – predictive maintenance strategies. By continuously tracking equipment performance and analyzing real-time data analysis, businesses can detect early warning signs for equipment failure and use this to provide proactive maintenance, thus minimizing downtime and repair costs.

6. Ensuring Compliance and Traceability

Real-time monitoring in the packaging industry is crucial to compliance and traceability, providing businesses with data that helps ensure products are packed correctly, labeled accurately, and meet regulatory standards. Furthermore, real-time monitoring enables end-to-end transparency that allows businesses to monitor products throughout their supply chains.

7. Understanding IoT and Connectivity Solutions

Real-time packaging operations monitoring is made possible thanks to IoT and connectivity technologies. Businesses using sensors, cameras, and other smart devices to collect and transmit real-time data enable seamless communication among various stages of the packaging process and, therefore, support efficient decision-making and problem-solving processes.

Final Thoughts

Real-time monitoring and video analytics have revolutionized the packaging industry, improving efficiency, quality control, and proactive maintenance. Companies leveraging real-time data can optimize processes while cutting costs – ultimately producing higher-quality products at reduced costs for market release. Technology will undoubtedly continue to advance, creating even greater advantages and driving growth within this sector.