Proactive Risk Prevention with Red Zone Monitoring using Computer Vision for Worker Safety

- Vathslya Yedidi

- May 2, 2025

Industrial operations are complex environments where significant safety risks accompany productivity and precision. Areas surrounding heavy machinery, automated systems, and hazardous processes present constant exposure to potential incidents. These high-risk areas require strict control to ensure worker safety.

For years, organizations have implemented safety protocols through training, signage, supervision, and access restrictions. While these measures are essential, they rely on human attention and often respond only after realizing a risk. Unsafe behaviors, near-misses, and unauthorized access frequently go undetected until serious accidents occur.

Global safety statistics emphasize the scale of this challenge. The International Labour Organization (ILO) reports approximately 2.9 million occupational deaths and 395 million nonfatal injuries each year. In the United States alone, 5,486 fatal workplace incidents occurred in 2022, with 2.6 million nonfatal injuries recorded in 2023.

To manage these risks more effectively, industries are adopting advanced technologies that enable continuous monitoring and early intervention. Red Zone Monitoring using Computer Vision for worker safety provides real-time hazard detection, oversight of restricted areas, and immediate alerts that help prevent incidents before they escalate.

This blog explores the importance of red zone monitoring in modern industrial environments and how Computer Vision enhances worker safety through intelligent, proactive solutions.

What is Red Zone Monitoring?

Red zone monitoring refers to the vigilant management of areas in industrial settings where unpredictable hazards and potential threats exist. These zones represent environments where accidents can occur without warning due to unforeseen mechanical failures, human error, or dynamic operational risks. Since such dangers cannot always be predicted, companies implement layered safety measures to reduce exposure, including barriers, alarms, floor markings, sensors, and active supervision. Red zones differ across industries based on specific operations. Still, the primary goal remains to proactively manage high-risk areas and ensure a quick response that protects workers from unforeseen dangers.

Understanding Red Zone Areas and Risks Across Industrial Sectors

Different industries have their own “red zones”, the common high-danger areas that demand special attention. The table below lists a variety of industries, examples of their typical red zone areas, and the key risks associated with those areas:

Industry

Typical Red Zone Areas

Key Risks in These Areas

Construction

Dynamic zones near cranes, suspended loads, excavation machinery, scaffolding, and demolition areas.

Severe injuries from falling objects, equipment strikes, structural collapses, and high-risk falls in elevated workspaces.

Manufacturing

Proximity to automated machinery, robotic arms, conveyor belts, presses, and forklift pathways on production floors.

Crushing, amputations, or entanglement due to machinery operations, plus collision risks with material handling vehicles.

Oil & Gas

Drilling platforms, high-pressure lines, flare stacks, and confined processing zones handling flammable substances.

Explosions, toxic gas exposure, fire hazards, and sudden pressure releases impact nearby personnel.

Warehousing & Logistics

Forklift operation zones, automated storage systems, loading docks, and pallet racking areas.

Pedestrian impacts from forklifts, falling inventory loads, and automation system movements pose collision hazards.

Chemical & Petrochemical

Chemical processing units, hazardous material storage, spill response zones, and tanker loading areas.

Toxic exposure, chemical burns, risk of fires or explosions, and inhalation hazards in poorly ventilated areas.

Utilities & Energy

High-voltage substations, turbine halls, live-line maintenance areas, and confined electrical spaces.

During active maintenance, electrocution, arc flashes, and mechanical hazards from rotating equipment or high-pressure systems.

Pharmaceuticalscy

Cleanrooms, hazardous drug compounding areas, containment labs, and restricted research zones.

Exposure to potent compounds, sterile environment breaches, and risks from improper handling of hazardous drugs.

Aerospace

Aircraft assembly lines, engine testing bays, maintenance hangars, and refueling zones.

Crushing from large aircraft components, fire hazards during fueling, and falls during elevated aircraft maintenance tasks.

The Role of Computer Vision in Preventing Accidents in Red Zones

Managing high-risk zones in industrial environments requires clear warning signs, physical barriers to block access, and staff actively monitoring the area. Worker Safety Monitoring with Computer Vision provides a practical solution by continuously watching these areas through Vision AI-powered video analysis. The system connects to existing camera networks and is configured to recognize specific safety parameters such as restricted access boundaries, mandatory PPE, safe distances from machinery, and time limits within hazardous zones. It analyzes live video feeds in real time to detect when a person enters a restricted area, fails to comply with safety protocols, or engages in unsafe behavior. When a violation occurs, immediate alerts are sent to supervisors or control rooms to allow rapid intervention before the situation escalates. The solution also records each event, creating a detailed log of safety breaches and near-misses. Helping organizations identify recurring risks, improve operational procedures, and strengthen safety practices.

Red Zone Monitoring Using Computer Vision Across Various Industries

1. Oil & Gas Industry

The oil and gas industry is one of the most hazardous work environments, where workers face risks from high-pressure systems, flammable substances, heavy machinery, and oil spillages that create serious slip hazards. Red zones on drilling platforms and processing units are especially high-risk areas where unexpected incidents can escalate quickly. Computer Vision-based Worker Safety Monitoring helps mitigate these risks by detecting unauthorized access, missing PPE, unsafe proximity to operating equipment, and oil spillages that pose slip dangers. The system provides real-time alerts to supervisors, enabling swift intervention to prevent serious accidents and injuries before they occur.

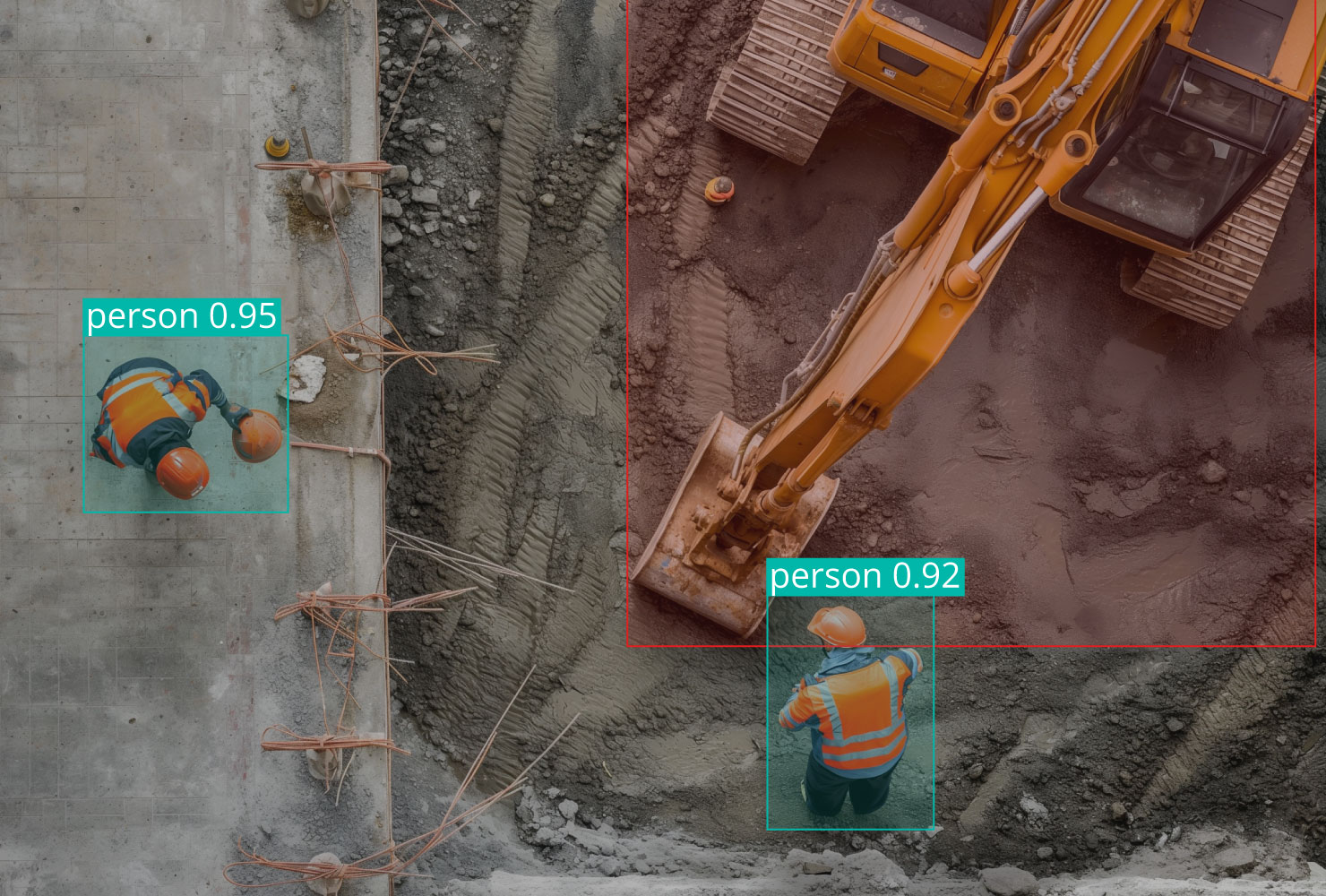

2. Construction Industry

Construction sites are dynamic environments where workers face constant dangers from moving machinery, falling objects, and unstable structures. Red zones typically surround cranes, scaffolding, and excavation areas where safety violations can result in severe injuries. Computer Vision supports worker safety by tracking live site conditions and identifying when personnel enter restricted zones or operate without proper protective equipment. These AI-powered systems adapt to shifting hazards, providing real-time alerts to supervisors whenever unsafe behavior or proximity to active machinery is detected, reducing the likelihood of accidents in construction settings.

3. Manufacturing Industry

Manufacturing environments expose workers to risks from automated machinery, robotic arms, and fast-moving assembly lines. Red zones are designated around equipment where human interaction can quickly turn dangerous if safety protocols are not followed. Computer Vision protects workers by monitoring these areas for unsafe approaches, verifying compliance with PPE requirements, and detecting hazardous behavior near operational machinery. When a worker crosses a danger zone without authorization or neglects safety measures, the system triggers immediate alerts, helping prevent injuries caused by unexpected human-machine interactions on the production floor.

4. Warehousing & Logistics

In warehousing and logistics operations, workers frequently navigate space with forklifts, conveyors, and automated guided vehicles, creating a risk of collisions. Red zones identify areas where close proximity to moving machinery can lead to serious accidents. Modern Computer Vision systems enhance safety by monitoring worker movements and vehicle operations in real time, detecting unauthorized entry, absence of visibility gear, and unsafe distances. Integrated surveillance cameras provide dynamic proximity alerts when workers come too close to moving equipment, ensuring operators and supervisors can respond immediately to prevent incidents.

5. Chemical & Petrochemical Industry

Workers in chemical and petrochemical plants face significant dangers from toxic substances, high-pressure systems, and flammable materials. Red zones restrict access to areas where exposure or accidents could be fatal. Computer Vision strengthens worker safety by monitoring entry points, confirming that only authorized personnel with appropriate protective equipment can access hazardous zones. These systems also detect unsafe behavior, such as lingering near critical equipment or ignoring safety protocols, and issue immediate alerts to prevent harmful exposure, ensuring a safer working environment in facilities handling dangerous chemicals.

6. Healthcare Facilities

In healthcare settings, strict safety standards are critical in high-risk areas such as operating rooms, isolation wards during infectious outbreaks, and laboratories handling hazardous biological materials. These environments require rigorous protocols to prevent contamination and protect staff and patients. Computer Vision enhances safety by monitoring access points, verifying personal protective equipment (PPE) use, and ensuring compliance with hygiene procedures like hand hygiene and mask usage. When deviations such as missing PPE or unauthorized entry are detected, the system sends immediate alerts, reinforcing infection control measures and helping safeguard medical personnel and patients in critical healthcare environments.

Conclusion

Effective management of high-risk zones is essential to maintaining safety in industrial operations. With the integration of Computer Vision, organizations gain a consistent and automated approach to monitoring hazardous areas, enabling faster risk detection and more efficient intervention. This solution supports existing safety frameworks by providing continuous oversight and insights, reducing the likelihood of incidents, and improving workplace safety standards.

Adopting such intelligent solutions will enhance operational safety and ensure compliance in complex environments as industries advance.

Contact us for more information on Red Zone Monitoring with Computer Vision for Workplace Safety.

Post Tags :

- Computer Vision in Industrial Safety

- Fall Detection Systems

- High-Risk Zone Control

- Industrial Accident Prevention

- PPE Compliance

- Real-Time Safety Alerts

- Red Zone Monitoring

- Safety in Chemical Plants

- Safety in Construction Sites

- Safety in Manufacturing

- Safety in Oil and Gas plants

- Worker Safety

- Workplace Hazard Monitoring

- Workplace Safety