Forklift Collision Avoidance System with Computer Vision for Accident Risk Reduction

- Vathslya Yedidi

- July 8, 2025

Forklifts are essential to material handling in warehouses, factories, and logistics hubs. They enable efficient movement of goods and maximize available space. At the same time, forklifts contribute to thousands of workplace accidents each year. In environments where people and vehicles operate in close quarters, maintaining situational awareness remains a challenge.

Traditional safety measures such as mirrors, audible alarms, and basic proximity sensors have been widely adopted but have known limitations. As facilities become more dynamic and as safety expectations rise, operators are looking for systems that reliably mitigate risks without unnecessary interruptions.

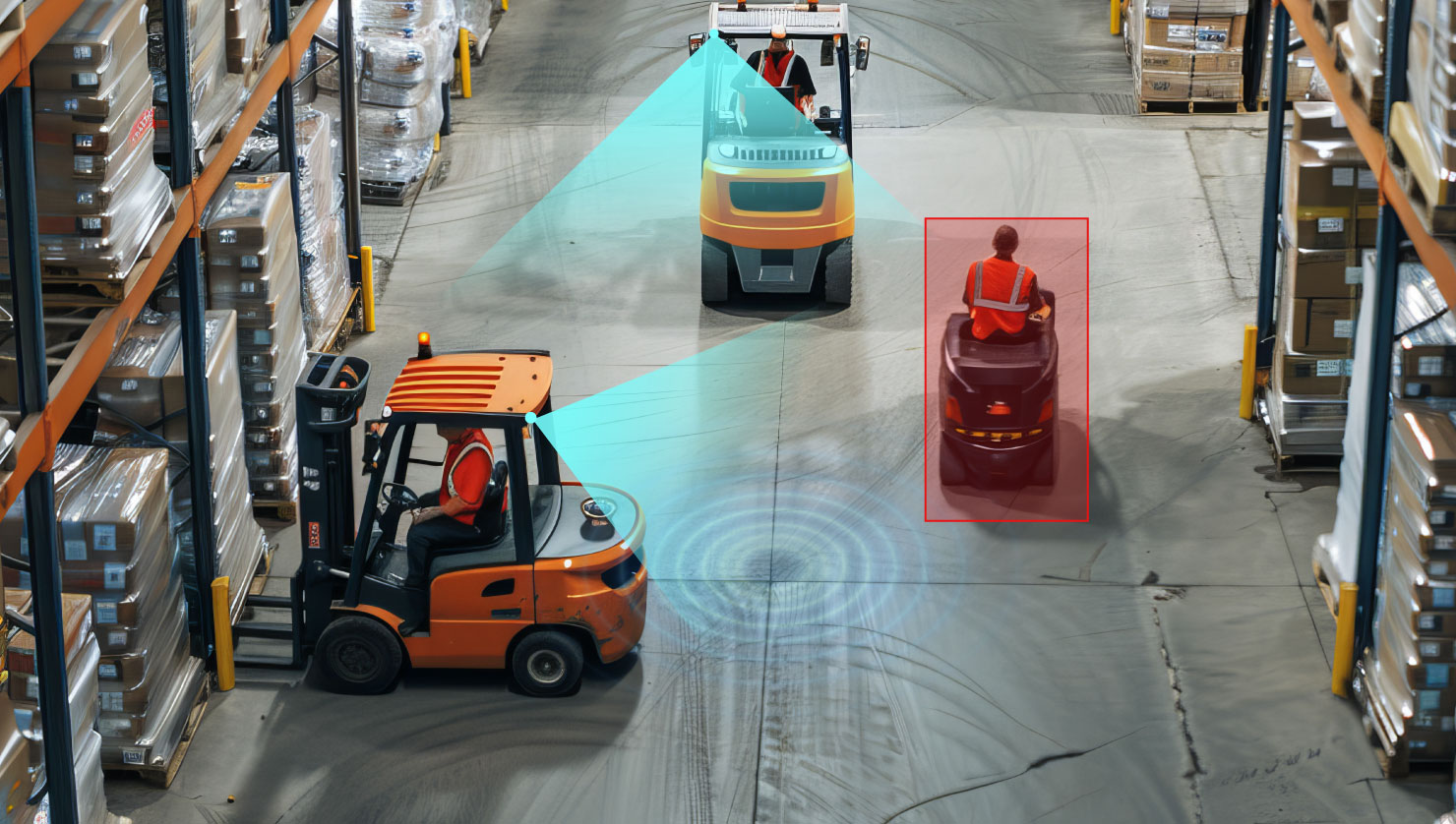

Computer Vision-Based forklift proximity alert for workplace safety addresses this need. Combining cameras, real-time processing, and AI-driven analysis, this collision avoidance system with Computer Vision offers a more accurate and effective way to monitor the forklift’s surroundings and inform operators of potential hazards. This blog explains how forklift-to-pedestrian distance monitoring with Computer Vision works and why they fit into modern industrial operations.

Gaps in Traditional Safety Measures

Most facilities today equip forklifts with standard safety features designed to reduce risk. Mirrors are installed to extend the operator’s view behind and alongside the vehicle. Backup alarms sound whenever the forklift reverses, warning pedestrians in the area. Some fleets also include ultrasonic sensors that trigger alerts when an object is detected nearby.

While these features contribute to safety, they are not designed to address the full complexity of a busy workplace. Mirrors rely entirely on the operator checking them at the right moment, which can be difficult when sightlines are blocked by loads or when maneuvering in tight spaces. As a result, blind spots persist, behind the forklift and around the mast.

Backup alarms provide a constant warning whenever the forklift reverses, regardless of whether anyone is present. In environments with multiple machines, workers quickly become accustomed to the noise and begin to ignore it. Similarly, ultrasonic sensors only measure the distance to the nearest object, without identifying whether it is a person, a rack, or stray material. Frequent false alarms diminish trust in the system and reduce its effectiveness. These factors show that traditional safety features have clear limitations in dynamic, high-traffic environments.

Why Pedestrian Safety Remains a Challenge?

Industrial environments where forklifts operate are among the most challenging spaces to keep pedestrians safe. Designated walkways, spotters, and warning signs help, but in busy, fast-moving areas, there are not enough. Collisions still happen usually in scenarios where visibility and awareness break down. Some of the most common high-risk situations include:

- Blind corners, where a forklift turns into a pedestrian unexpectedly.

- Loading and unloading zones, crowded with people and vehicles moving simultaneously.

- Narrow aisles, forcing forklifts and pedestrians into close proximity with little room to maneuver.

- Reversing forklifts, where rear visibility is limited.

- Distracted workers, either operators or pedestrians, unaware of their surroundings.

These scenarios highlight how easily traditional safeguards can fail, and why a more intelligent, real-time approach to pedestrian safety has become essential.

How Computer Vision for Forklift Collision Avoidance System Works?

Forklift Accident Prevention with Computer vision-based systems take a fundamentally different approach. Instead of relying on basic distance measurements or constant audio warnings, they analyze visual data to understand the forklift’s environment in real time.

Cameras mounted on the forklift capture live video of the surrounding area. These connect to an onboard processor running AI models trained in industrial environments. The system detects people, vehicles, pallets, racks, and fixed infrastructure and can distinguish between them. Once an object is detected, the system calculates its distance and trajectory relative to the forklift. Safety zones are defined around the vehicle. For example, a caution zone extending several meters and a danger zone closer in. When a person or obstacle enters these zones, the system triggers the appropriate alert with an advanced Computer Vision proximity alert system designed to reduce false alarms and improve operator focus.

Because it understands what it sees, the system avoids unnecessary alarms. It does not issue the same warning for a fixed wall outside the forklift’s path as it does for a pedestrian walking into the vehicle’s path. This context-awareness keeps operators focused on relevant risks.

Real-Time Detection and Continuous Tracking

An important advantage of Computer Vision-based systems is their ability to maintain continuous awareness of detected objects through precise proximity detection. Once a person or obstacle is identified, the system tracks its position dynamically, even if it becomes partially obscured by loads or infrastructure. As both the forklift and surrounding elements move, the system updates its calculations in real time, ensuring alerts reflect the current situation with high accuracy. This level of responsiveness and persistence is not achievable with mirrors or simple point sensors.

Prioritized, Context-Aware Alerts

When a defined safety threshold is breached, the system delivers targeted, context-aware alerts to the operator. Inside the operator’s cabin display shows where the hazard is located such as to the left, right, or rear, while audible and visual indicators prompt the operator to slow or stop. Alerts are tiered by proximity and severity: for example, a pedestrian entering a caution zone may trigger a visual warning, while entering a critical zone triggers a louder, more urgent alarm. This graded approach enables quick, informed reactions without overwhelming the operator with unnecessary signals.

Why Computer Vision-Based Forklift Safety Systems Are Being Adopted?

The consequences of forklift-related incidents go beyond immediate injuries. Collisions disrupt workflows, damage goods and equipment, raise insurance exposure, and challenge workforce confidence. Forklift-to-forklift and forklift-to-pedestrian proximity detection with Computer Vision mitigates these risks while supporting broader operational goals:

- Clear Operational Awareness: Operators have a real-time, comprehensive view of surrounding activity without relying on manual checks or guesswork.

- Fewer Collisions and Less Downtime: Early, graded alerts help prevent incidents, keeping operations moving without costly disruptions.

- Greater Operator Confidence and Efficiency: Intelligent support allows forklifts to maintain safe speeds in congested areas, without hesitation.

- Safety Performance Data: Logged events and trends inform improvements to layouts, traffic flows, and training programs over time.

Integrating forklift-to-pedestrian distance monitoring with Computer Vision, facilities achieve higher safety standards, more predictable operations, and measurable improvements in both efficiency and well-being of the workforce.

Conclusion

Facilities that rely on forklifts operate in environments where decisions must be precise and risks managed deliberately. Traditional safeguards introduce uncertainty that operators cannot always compensate for.

Computer vision-based systems resolve these gaps by delivering comprehensive visibility and the insight required to support accurate, timely decisions.

Contact us to learn how this capability can be deployed within the operations.