Worker Safety Monitoring in Oil and Gas

Vision AI for Worker Safety Monitoring in Oil and Gas Operations

Constant vigilance is essential for worker safety in oil and gas operations. Computer Vision technology provides thorough, real-time monitoring and ensures compliance with safety standards. Using Vision AI in drones further extends this capability, significantly improving hazard detection and ensuring comprehensive protection for personnel.

Bridging the Gap in Real-Time Safety Monitoring for Oil and Gas Workers

Without advanced safety monitoring solutions, oil and gas facilities face several critical challenges:

- Increased Hazardous Risks: Unmonitored areas may pose unknown threats, leading to accidents or health hazards.

- Operational Inefficiencies: Lack of real-time monitoring results in oversight failures, impacting safety and efficiency.

- Compliance and Reporting Issues: Insufficient safety logs risk non-compliance with HSE regulations, incurring penalties.

- Delayed Emergency Response: Slow hazard detection increases risks during emergencies.

- Insufficient Surveillance Coverage: Traditional systems often miss complex or expansive areas, leaving critical zones unmonitored.

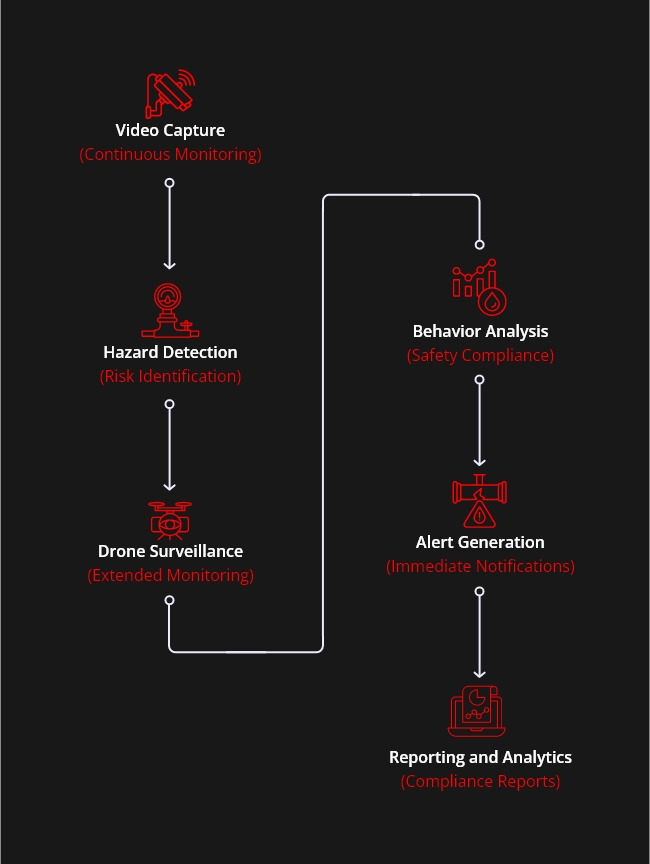

Process Flow of Worker Safety Monitoring Using Computer Vision

Our process offers a comprehensive approach to maintain and enhance worker safety in oil and gas fields through the strategic deployment of advanced technologies:

- Video Capture: High-definition cameras are strategically placed to continuously monitor worker activities and environmental conditions, enhancing real-time observation and ensuring compliance with safety protocols.

- Hazard Detection: Computer Vision algorithms analyze video feeds to detect equipment malfunctions, structural weaknesses, and unsafe behaviors, ensuring timely identification of risks that could cause accidents.

- Drone Surveillance: Drones with high-resolution cameras extend monitoring into hard-to-reach areas, capturing data on environmental hazards like gas leaks and providing a broader safety view than traditional systems.

- Behavior Analysis: The system monitors worker behavior and practices, identifying unsafe actions and promoting adherence to safety best practices, creating a proactive safety culture.

- Alert Generation: When hazards or unsafe actions are detected, safety managers are alerted immediately, allowing for quick interventions and effective risk mitigation.

- Reporting and Analytics: The platform generates detailed reports on compliance, hazard detection, and behavior analysis, helping improve safety protocols and maintain a safe working environment.

EHS Solutions for Oil and Gas Workers with Advanced Safety Monitoring

The Workplace Safety Monitoring solution for Oil and Gas is designed to vigilantly oversee each worker’s safety, ensure proper PPE usage, and monitor behavior in hazardous environments.

- Worker Tracking and Monitoring: Real-time surveillance through Computer Vision technology continuously tracks worker movements, significantly enhancing safety and compliance.

- Hazard Detection: Drones equipped with Vision AI rapidly identify potential dangers like gas leaks or malfunctioning equipment, extending coverage and improving response times.

- PPE Compliance: Computer Vision technology automatically verifies that all workers are equipped with the required safety gear, thus reducing the risk of injuries.

- Unauthorized Access Detection: Vision AI actively monitors and alerts security personnel of any unauthorized entries, helping protect sensitive areas and infrastructure.

- Damage Assessment: In the event of an incident, drones quickly perform assessments to pinpoint damages and enable swift, effective remediation.

Hazard Assessment in Oil and Gas Facilities for Better Worker Safety

Worker Safety Monitoring with Vision AI introduces a new standard of risk prevention for oil and gas facilities. Real-time analysis of potential hazards helps protect workers and ensure compliance by addressing risks before they escalate. This advanced solution enhances safety management and boosts productivity through proactive risk mitigation.