Grated Cheese Packet Seal Inspection with Computer Vision

- Vathslya Yedidi

- August 21, 2025

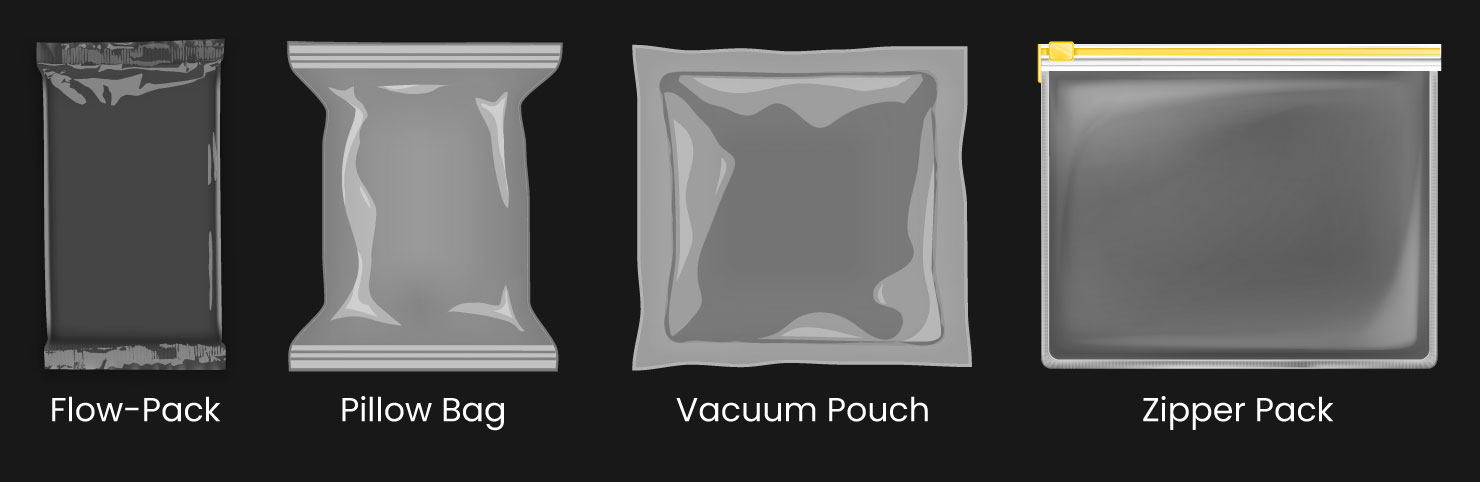

Grated cheese is one of the fastest-moving products in the dairy industry, packaged in high volumes for both home kitchens and commercial food service. Modern production lines are built for speed, sealing thousands of packets every hour in formats such as flow-packs, pillow bags, and resealable pouches. These packs are sealed under modified atmosphere conditions (MAP) to lock in freshness and extend shelf life.

Yet, behind this efficiency, the integrity of the seal remains the true safeguard of quality. A single trapped shred of cheese, a wrinkle in the film, or a slight temperature variation at the sealing jaws can compromise the barrier designed to keep oxygen and contaminants out. These flaws, invisible to the naked eye, carry serious consequences: premature spoilage, altered taste, health risks, and costly recalls. In March 2025, for example, Aldi recalled 5,000 Happy Farm’s Colby Jack Deli Sliced Cheese pouches across four U.S. states after potential stainless-steel fragments were found, showing how fragile packaging integrity can put brands at risk.

Traditional inspection methods, manual checks and random sampling struggle to keep pace with production speed and precision requirements. Defects slip through, reaching consumers before they are noticed, damaging both trust and efficiency.

Computer Vision brings a modern solution. With high-resolution imaging, real-time processing, and AI-driven detection, grated cheese packet seal inspection with Computer Vision can now be performed 100% inline, without slowing production.

Grated Cheese Manufacturing and Packaging Process Overview

From raw milk to sealed packet, every stage in cheese production influences quality and safety. Knowing this journey shows why seal integrity is so critical.

Production begins with fresh milk sourced from dairy suppliers. Each batch is tested for temperature, composition, and microbiological safety before being standardized and pasteurized to preserve flavor while eliminating harmful bacteria.

Starter cultures and rennet are then added to form curds, which are cut, stirred, and heated to separate whey. The curds are pressed into blocks and aged under controlled conditions until they develop the desired texture and taste.

Once matured, the cheese is shredded into uniform strands to ensure smooth portioning and consistent packaging. The shredded cheese is then moved to the packaging line, portioned into retail or foodservice packs, and sealed using heat, pressure, and timing to create a secure barrier that locks in freshness and protects against contamination.

Various Packaging Formats for Grated Cheese

Grated cheese is typically packed in flexible and convenient formats designed to preserve freshness and meet consumer needs:

- Flow-Packs: Lightweight packs sealed quickly on high-speed lines, widely used for everyday retail portions.

- Pillow Bags: Similar to flow-packs but with a larger surface area, suitable for family-size or bulk packs.

- Vacuum Pouches: Extend shelf life by removing air before sealing, used for premium or larger volumes.

- Reclosable Zipper Packs: Provide convenience with easy resealing, increasingly popular for regular household use.

Challenges in Detecting Seal Defects in Cheese Flow Packs

Inspecting seals in real time is far more complex than it might seem. Several operational, material, and environmental factors combine to make defect detection a persistent challenge.

- Variability in Packaging Film: Glossy or metallized films create reflections that obscure faults.

- Product Residue at the Seal Zone: Fine shreds or fat deposits create micro-leaks that shorten shelf life.

- Inconsistent Sealing Conditions: Minor deviations in jaw temperature, film tension, or pressure can cause weak seals or wrinkles.

- Limited Visibility with Printed or Opaque Films: Graphics and branding overlap the seal area, making edge continuity harder to verify.

- High-Speed Production: At 80–120 packs per minute, manual inspection misses intermittent defects.

- Micro-Defects Before Failure: Tiny channels or incomplete fusion cause later failures, invisible during casual checks.

- Gradual Process Drift: Wear or buildup on sealing jaws slowly degrades seal quality, with problems compounding over time.

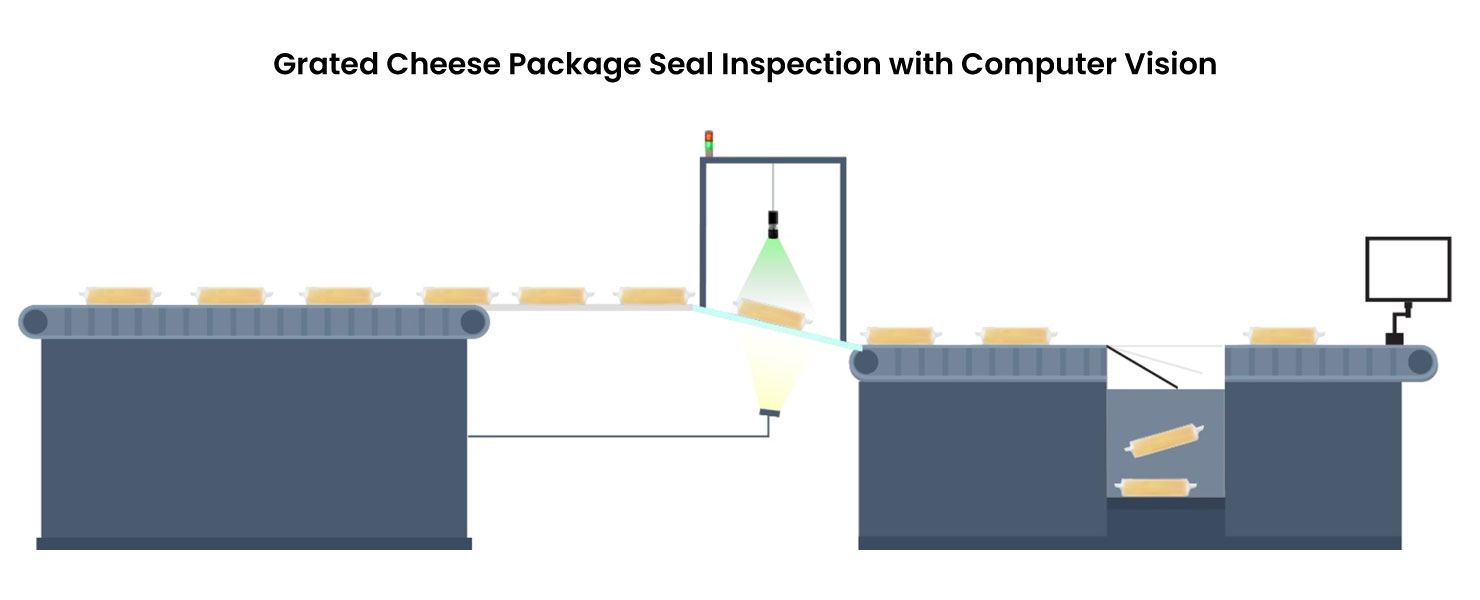

Computer Vision System for Inspecting Cheese Flow Pack Seals

Grated cheese package seal inspection using Computer Vision solution is designed to overcome package seal integrity challenges by providing precise, high-speed, and fully automated seal analysis.

After sealing, each cheese packet passes into an inspection unit. High-resolution cameras, paired with diffuse lighting, capture detailed images of the entire seal. This setup, i.e., seal quality inspection with Computer Vision, reduces glare from glossy or printed films and highlights trapped particles, folds, or incomplete seals.

AI-powered algorithms, trained on thousands of seal images, analyze each pack for uniformity, contamination, and structural flaws. Some systems also integrate thermal imaging to detect poor heat transfer before defects progress further.

Decisions are made in milliseconds, allowing defective packs to be automatically rejected without slowing production. Each rejection is logged with defect type, timestamp, and image evidence, providing traceability and insights for upstream adjustments. This feedback loop helps maintain consistent quality and reduces overall defect rates.

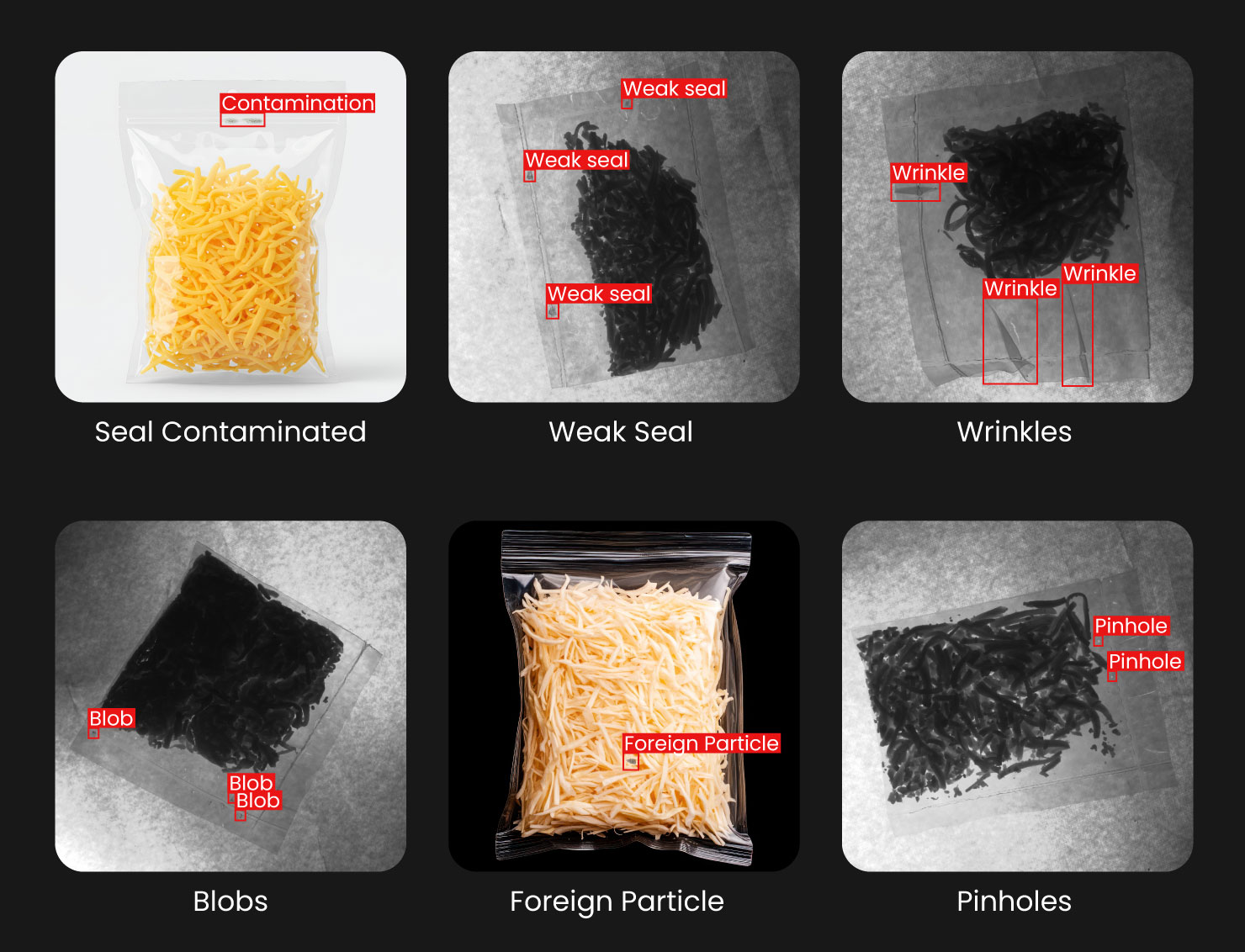

Defects Identified During Grated Cheese Package Seal Inspection with Vision AI

In grated cheese packaging, seal defects can arise from equipment issues, process deviations, or material inconsistencies. Detecting these faults in real time is essential to preserve product quality, extend shelf life, and maintain compliance. Common defects include:

- Product-in-Seal Contamination: Cheese shreds, fat, or moisture trapped in the seal zone.

- Weak or Incomplete Seals: Insufficient heat, pressure, or dwell time leading to leaks.

- Wrinkles and Creases: Film distortion that creates channels for oxygen ingress.

- Air Bubbles or Blobs: Entrapped air pockets disrupting seal uniformity.

- Spoiled Product: Mold, discoloration, or odor from oxygen or moisture infiltration.

- Foreign Particle Contamination: Film fragments, dust, or other particles within the seal.

- Incorrect Packet Dimensions: Misaligned packs that compromise seal strength.

- Micro-Leaks and Pinholes: Minute openings that reduce shelf life.

Conclusion:

Integrating Computer Vision into grated cheese packaging equips manufacturers with the ability to inspect every seal, detect every defect, and protect every pack in real time. Replacing sampling with inline monitoring, brands can cut waste, prevent recalls, and deliver products that consistently meet the highest safety and quality standards.

Seal integrity is too critical to leave to chance. Cheese package seal inspection with Vision AI enables manufacturers to reduce waste, prevent costly recalls, and safeguard brand trust. Get in touch to explore implementation in operations.