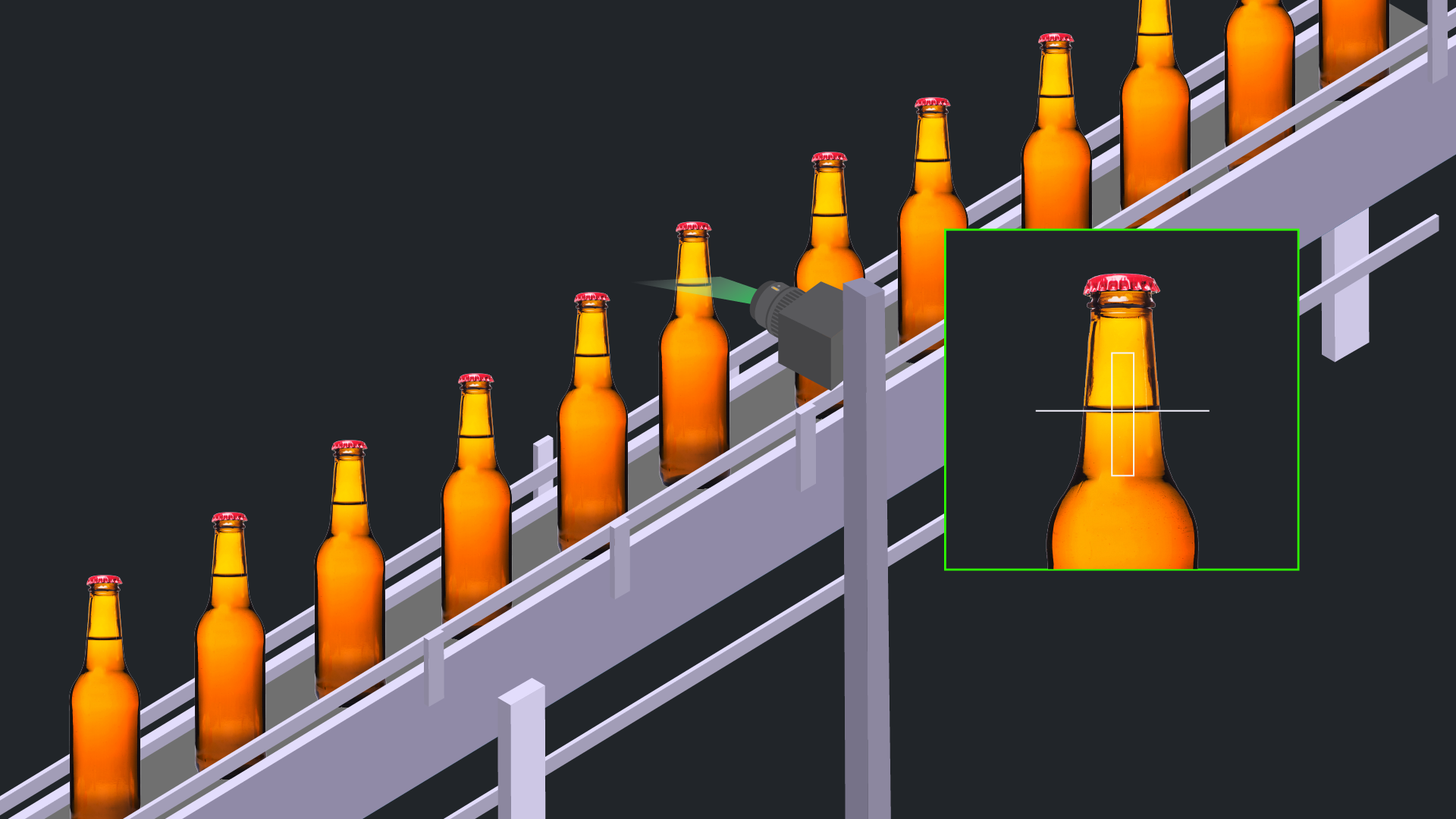

Fill Level Inspection with Vision AI in Bottles for Consistent Quality

- Vathslya Yedidi

- December 9, 2024

Manufacturing processes across industries, from raw material handling to electronics production, rely heavily on quality control to ensure uniformity in products meeting the same specifications. This practice is key to building a brand’s reputation, fostering customer loyalty, and maximizing profits. Accurate fill level monitoring is essential in various industries like pharmaceuticals, beverages, chemicals, food processing, cosmetics, and household products, where precision directly impacts quality, safety, and profitability. Underfilled bottles can lead to customer dissatisfaction and legal consequences, while overfilled products result in financial losses.

Traditionally, quality assurance for fill levels involves routine inspections by trained staff. While this method is widely used, it is labor-intensive, costly, and inherently subjective, as individual assessments can vary despite standardized training. Many manufacturing sectors have turned to automated systems powered by Vision AI to address these limitations. Using cameras and image processing, these systems monitor defects and inconsistencies in production lines, offering benefits such as reduced human bias, lower labor costs, faster processing times, and minimized human contact, which helps prevent contamination.

In this blog, we will explore the significance of Fill Level Inspection with Vision AI in Bottles, the challenges of traditional methods, and how Vision AI improves quality control in industrial manufacturing processes.

What is Fill Level Monitoring in Bottles for Quality Control?

Fill level monitoring refers to inspecting containers, such as bottles, to ensure they are filled to specified volume levels. This systematic process involves determining whether a container’s liquid level is within acceptable thresholds recognized by industry standards. In manufacturing, liquid level detection in bottles and containers is critical for identifying underfilled or overfilled products and maintaining consistency across production lines.

Key Role of Fill-Level Monitoring in Automated Quality Assurance

Fill-level monitoring is essential in modern manufacturing to deliver precision and reliability in production processes.

Quality Control: Vision AI inspection systems improve product quality management by providing instantaneous, objective measurements of liquid fill levels. This eliminates human error and ensures consistent, reliable quality checks across production lines.

Regulatory Precision: In highly regulated industries such as pharmaceuticals, beverages, and food production, automated fill level monitoring is essential. These systems guarantee that every container meets exact regulatory specifications, providing verifiable documentation of compliance with strict quality standards.

Operational Optimization: Real-time fill-level Inspection with Vision AI generates valuable data that enables manufacturers to detect and correct filling inconsistencies instantly, reduce product waste, minimize production line interruptions, and optimize manufacturing processes with data-driven insights.

Economic Impact: Automated inspection systems directly reduce costs by preventing overfilling and underfilling. They minimize material waste, reduce the risk of product recalls, and help maintain consistent product volumes that protect profit margins.

Advanced Algorithms Integration: Modern fill-level monitoring leverages Computer Vision algorithms and high-speed sensors to deliver unprecedented accuracy and speed in quality assurance.

Challenges in Fill-Level Inspection Across Industries

Fill-level inspection is crucial in maintaining product quality and safety across industries. However, real-world scenarios present challenges that manufacturers must address to ensure accurate and efficient monitoring:

Dealing with Transparent or Opaque Containers

In industries like beverages and pharmaceuticals, containers can be clear, tinted, or completely opaque (e.g., amber bottles). Inspecting fill levels in opaque bottles is particularly challenging as the liquid is not visible to standard sensors or visual inspection systems.

Foaming in Carbonated or Viscous Liquids

Carbonated beverages or foamy products can create bubbles that obscure the fill level. Similarly, viscous liquids such as syrups or creams may settle unevenly during high-speed filling, complicating accurate level detection.

Variations in Bottle Sizes and Shapes

Packaging diversity, such as irregularly shaped bottles or varying container sizes, requires flexible inspection systems that can adapt to different configurations without compromising accuracy.

Inconsistent Liquid Flow Rates

Changes in liquid flow rates during production, caused by equipment malfunctions or variations in fluid properties, can lead to inconsistent fills, making inspections more complex.

High-Speed Line Operations

Modern manufacturing demands rapid production lines to meet high output requirements. Inspecting fill levels accurately at high speeds is difficult as it requires real-time data analysis and immediate adjustments to avoid disruptions.

Impact of Environmental Factors

Lighting, temperature fluctuations, and even vibration on production floors can interfere with Vision AI system’s performance. For instance, poor lighting can affect camera-based inspections, leading to false positives or missed defects.

Product Adherence to Bottle Walls

Certain products, like oils or sauces, can cling to the sides of bottles, giving the appearance of an incorrect fill level during inspection. This often leads to rejections or unnecessary adjustments.

Regulatory Compliance

Industries like pharmaceuticals and food must adhere to strict regulatory standards for fill levels. Ensuring compliance while minimizing waste and maintaining efficiency poses significant challenges, especially when transitioning from manual to automated inspection systems.

Defining the Process of Fill-Level Inspection Using Computer Vision

Integrating Vision AI systems offers a robust solution to address the challenges in fill-level monitoring. These systems use image processing and Computer Vision algorithms to assess fill levels accurately across various container types and production environments. The process of fill-level inspection with Computer Vision is as follows:

Grayscale Conversion and Noise Reduction

The process begins by converting the input image to grayscale, simplifying it by removing color information. This step reduces computational complexity while retaining the essential details needed for analysis. Gaussian blur is applied to further prepare the image for accurate edge detection. This smoothing technique minimizes noise and enhances the clarity of edges, ensuring a reliable foundation for subsequent steps.

Edge Detection Using the Canny Algorithm

After preprocessing, the Canny edge detection algorithm is applied. This method identifies significant edges in the grayscale image, highlighting boundaries such as the liquid level in a container. The algorithm prepares the image for precise contour detection by focusing on these prominent features.

Contour Detection and Plotting

With the edges highlighted, the next step is identifying and mapping contours within the image. Contours are closed shapes or boundaries that delineate distinct regions. This step isolates critical features, such as the liquid surface or bottle structure, providing a clear visual framework for analysis.

Setting a Fill Level Threshold

A fill-level threshold is established to define acceptable regions within the container. This threshold acts as a benchmark, specifying the expected liquid level. Comparing the detected features against this reference, the system determines whether the fill level meets the required standard.

Region of Interest (ROI) Masking

To focus on the analysis, a mask is applied to isolate the region of interest. Areas outside the defined threshold are excluded, ensuring only relevant parts of the image, such as individual bottles or the liquid surface, are analyzed. This step streamlines the process by concentrating on computational resources where they are most needed.

Line Detection with Hough Transform

The Hough Transform is employed within the masked region to identify straight lines. These lines often correspond to structural or fill level boundaries, providing a clear reference for comparing the detected liquid level against the set threshold.

Visual Output and Status Display

Finally, the analyzed image is displayed with status labels for each bottle. Based on the fill-level analysis, each region is marked as “Pass” or “Fail.” This visual overlay provides immediate, actionable insights into the level status, enabling swift decision-making and adjustments if needed.

Conclusion

Fill-level monitoring is essential for maintaining product quality, regulatory compliance, and operational efficiency in manufacturing. Challenges such as handling diverse container types, managing high-speed production lines, and addressing environmental interferences require advanced and reliable solutions.

Vision AI effectively addresses these challenges, offering precision and consistency while reducing reliance on manual inspections. Its adaptability ensures seamless integration across diverse production environments, making it a trusted choice for manufacturers aiming to enhance their quality control processes.

Contact today to learn more about fill-level monitoring with Vision AI solution.