Automated Gauge and Meter Reading

Gauge Meter Reading Using Computer Vision for Oil and Gas Industrial Settings

Accurate gauge readings are essential in demanding environments like oil and gas, which have extreme conditions and high safety risks. Relying on manual monitoring of outdated analog gauges increases exposure to hazards and reduces operational efficiency. Automated solutions powered by Computer Vision offer precise, real-time readings from a safe distance, enabling safer and more streamlined operations in these challenging oil & gas industrial plants.

The Risks and Inefficiencies of Manual Gauge & Meter Reading

The limitations of manual gauge & meter reading create multiple challenges:

- Time-Consuming Process: A cycle for reading several gauges may take a few hours, especially in large facilities.

- Low Reading Accuracy: Misapprehension can result from parallax errors, poor visibility, or the difficulty of the gauge’s face.

- Maintenance Blind Spots: Randomly infrequent readings can lead to missed critical deviations between rounds of manual inspections.

- Documentation Errors: Manual recording of values leads to transcription errors and delays in data entry into systems.

- Resource Intensive: Requires dedicated personnel for continuous monitoring, increasing operational costs.

Interpreting Precise Readings with Gauge Meter Reading Using Computer Vision

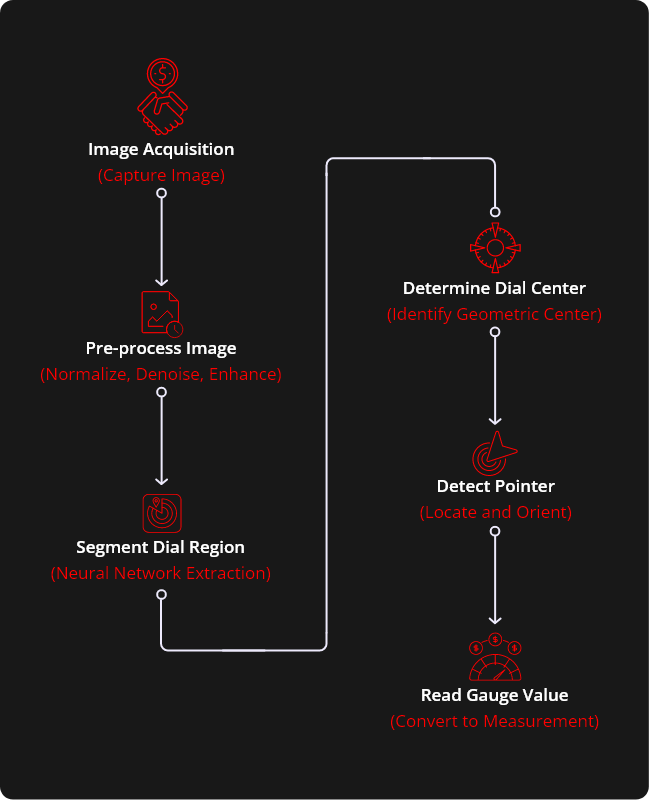

Implementing automated gauge and meter reading using Computer Vision in oil and gas facilities involves several key steps:

- Image Acquisition: Cameras capture high-resolution images or video streams of analog gauges, ensuring accurate data collection in industrial environments.

- Image Preprocessing: Captured images are enhanced using noise reduction, contrast adjustment, and alignment correction to prepare them for analysis.

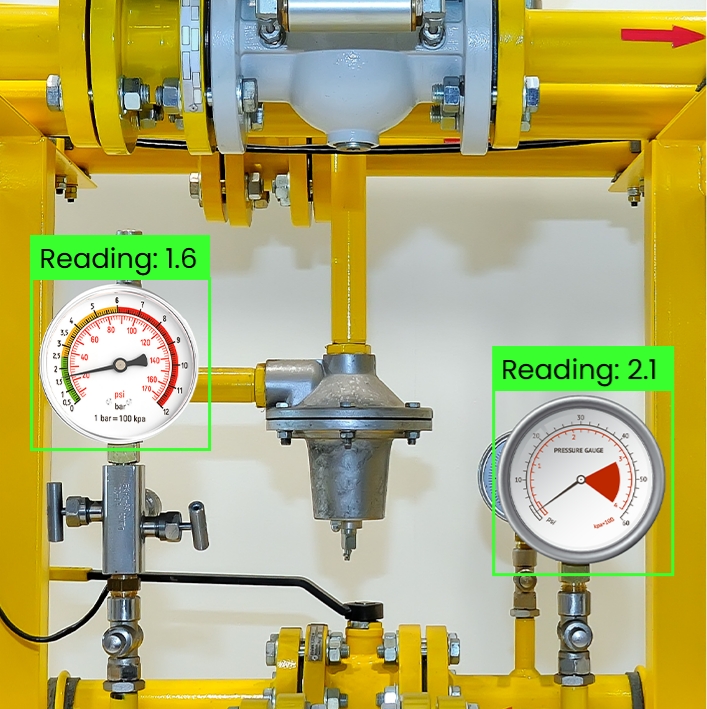

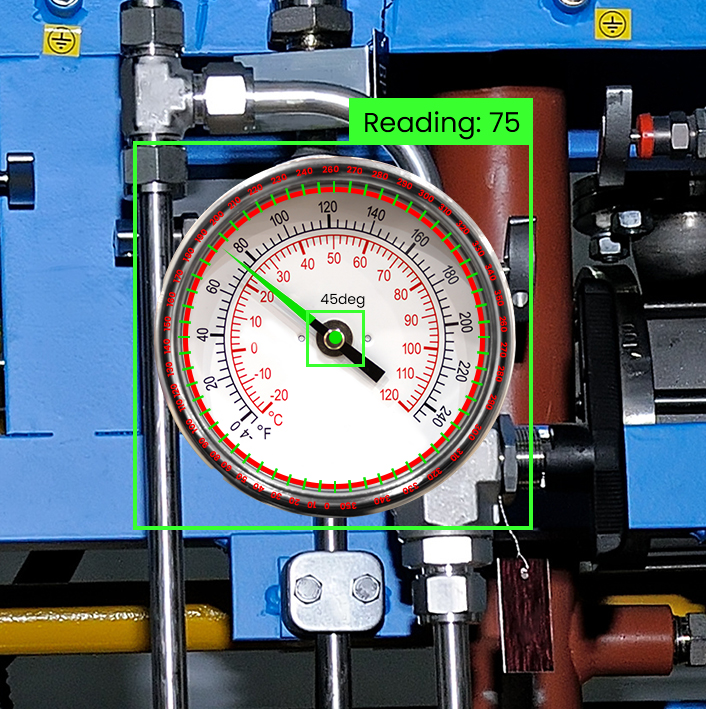

- Gauge Detection: Computer Vision algorithms identify the gauge face, isolating critical elements like the needle or display from the background.

- Reading Interpretation: The system uses Optical Character Recognition (OCR) to analyze needle positions or extract data from digital displays.

- Data Transmission and Alerts: Extracted readings are securely transmitted to centralized systems for storage and real-time monitoring. Alerts are triggered for threshold deviations.

- Logging and Integration: All readings and events are logged, enabling trend analysis and seamless integration with plant systems for improved monitoring and decision-making.

Real-Time Capabilities with Analog Meter Reading Using Computer Vision

Automated gauge and meter reading with Computer Vision delivers accurate, real-time monitoring, reducing manual errors and enabling proactive risk management in critical oil and gas operations.

- Irregular Reading Alerts: Automatically detect and highlight deviations in gauge or meter readings from predefined thresholds, ensuring anomalies are addressed promptly.

- Deviation Monitoring: Continuously monitor and identify unexpected changes in gauge readings, helping to prevent operational disruptions before they escalate.

- Real-Time Variance Detection: Detect immediate shifts in gauge performance, enabling rapid responses to fluctuations that could signal potential issues.

- Threshold Breach Notifications: Notify operators instantly when readings exceed safe operational limits, preventing equipment failure or safety incidents.

- Critical Reading Alerts: Focus on identifying critical deviations that require immediate attention to avoid operational risks and maintain plant integrity.

Empower Your Plant with Analog Gauge Monitoring Using Computer Vision

Automated Analog Meter Reading with Computer Vision introduces a smarter way to monitor analog gauges in oil and gas operations. This advanced solution delivers accurate, real-time readings, eliminating the need for manual checks in high-risk environments. With continuous monitoring and actionable insights, teams can respond swiftly to potential issues, maintain compliance, and minimize operational risks, ensuring a safer and more efficient workplace.