Raising the Bar for Safety & Sustainability in Chilled Carton Packaging with Vision AI

- Vathslya Yedidi

- January 12, 2024

Have you ever thought about the chilled cartons (milk or any cold drinks) packages that keep the food fresh on the shelves at the grocery store? It’s a complex task: ensuring food safety without harming the environment. The food and manufacturing industries constantly seek ways to protect food while being eco-conscious. To prioritize consumer trust, industry reputation, safety, and sustainability, packaging companies are now exploring Vision AI technologies for Quality Verification and Inspection of chilled carton packaging.

The preservation of food, ensuring its safety, and promoting sustainability are predominant in modern chilled carton packaging solutions. These packages are widely used to safeguard perishable food items such as dairy products and beverages, providing protection against external contaminants and extending shelf life. However, the utilization of traditional packaging quality verification methods has raised concerns regarding their alignment with sustainability standards.

In this blog, we’ll delve into Vision AI’s role in quality checks for chilled carton packages, focusing on how it enhances safety and sustainability standards. Addressing these aspects upholds product integrity, meets global standards, and fosters consumer trust.

The Role of Vision AI in Chilled Carton Packaging

Leveraging Computer Vision, Deep Learning, and imaging capabilities, Vision AI in Chilled Carton Packages offers real-time monitoring and analysis of the product’s condition of carton products. This technology allows for:

- Quality Assessment: Vision AI for Packaging Inspection can swiftly detect any anomalies or defects in packaged food items, ensuring that only products meeting quality standards are distributed.

- Shelf-Life Prediction: By analyzing various factors such as temperature, humidity, and package integrity, AI Vision Systems can accurately predict the remaining shelf life of the contents, reducing food wastage.

- Environmental Impact Mitigation: Smart packaging enables precise monitoring of environmental conditions, optimizing storage and transportation parameters to minimize energy consumption and reduce the carbon footprint.

- Enhancing Consumer Trust: With increased transparency and reliability in food safety measures, AI-driven Quality Checks boost consumer confidence by ensuring the freshness and integrity of the products they purchase.

Vision AI’s Impact on Safety and Sustainability Standards

The adoption of Vision AI in chilled carton packaging significantly elevates safety and sustainability benchmarks within the industry. By addressing crucial factors such as product integrity, environmental concerns, compliance with global standards, and consumer trust, these smart packaging solutions pave the way for:

- Reduced Food Waste: Accurate shelf-life predictions lead to minimized food wastage at both consumer and industrial levels, contributing to a more sustainable food supply chain.

- Eco-friendly Practices: Optimization of packaging materials and transportation processes through AI-driven insights promotes environmentally conscious practices, aligning with global sustainability goals.

- Industry Reputation: The commitment to safety and sustainability fosters a positive industry reputation, positioning companies as responsible stewards of both consumer well-being and the environment.

Pioneering Excellence in Carton Packaging Products with ImageVision.ai

Safeguarding consumer safety is crucial and necessitates strict adherence to regulations. Through the implementation of Vision AI in production lines, companies can ensure compliance and safety standards by conducting thorough inspections and verifications to enhance product integrity and authenticity.

1. Tamper Detection (Seal, Color, Forensic): Equipped with vigilance, Vision AI diligently detects the signs of tampering by carefully examining seals, inspects the packaging for color consistency in logos, texts, or patterns, and checks for forensic evidence such as hidden alterations, marks, or physical anomalies which may indicate unauthorized interference.

2. Printing/Label/Bar Code Check: With unrivaled precision, Vision AI meticulously verifies printing quality, assures label accuracy, and validates barcode functionality, resulting in precise and legible information on every package.

3. Dimension Detection: With meticulous attention to detail, Vision AI Inspection guarantees exact compliance with specifications by thoroughly scrutinizing the measurements of packaging materials, thereby maintaining uniformity and ensuring high quality.

4. Count Verification in Cartons: Powered by unparalleled accuracy, Vision AI accurately counts and verifies the number of products within cartons, guaranteeing consistency and correctness.

5. Surface Defect Detection: By swiftly detecting deformities such as dents or cracks in cartons, Vision AI effectively prevents compromised product safety due to structural damage.

6. Liner Completeness Verification: With thorough attention to detail, Vision AI critically examines the integrity of liners, ensuring that packaging materials are complete and secure.

7. Analysis of Glue Gaps: Vision AI identifies any gaps or irregularities in glue application, thus ensuring proper sealing and structural strength of the packaging.

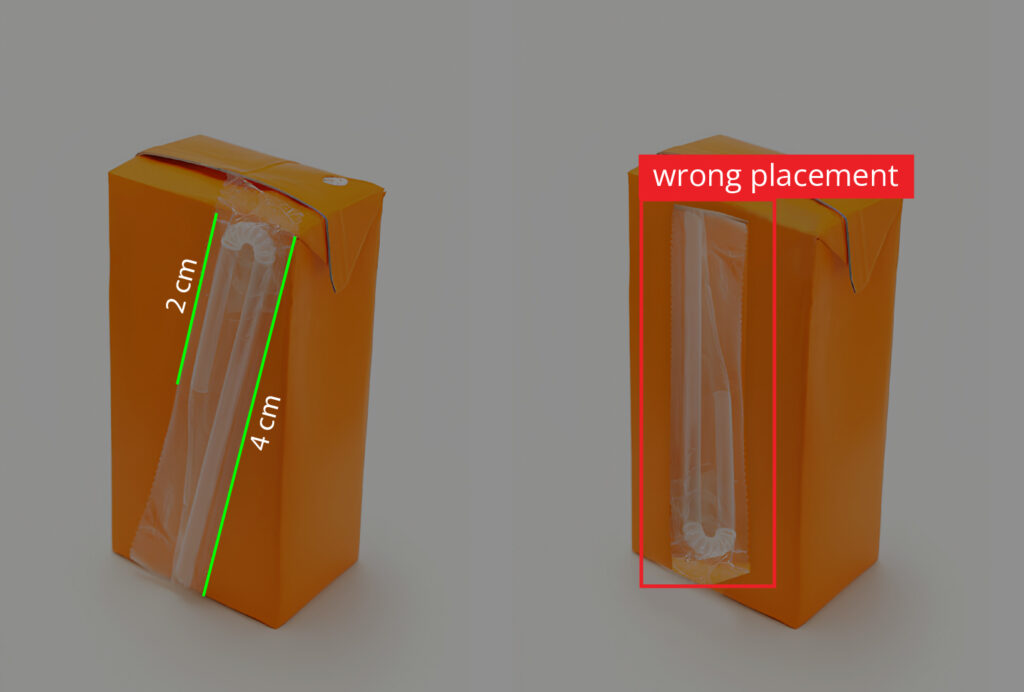

8. Inspection for Straw Inclusion and Measurement: Vision AI rigorously checks packages that contain straws to ensure proper inclusion, accurate placement, and precise measurement adherence, thereby guaranteeing compliance with packaging standards.

With the capabilities of Vision AI, the food packaging industry can enhance safety and compliance, ultimately protecting the well-being of consumers.

Food Industry Giants Achieves Remarkable Results with Vision AI

Industry giants such as Nestlé, DHL, and Coca-Cola stand as prime examples of Vision AI’s transformative impact. Through Computer Vision, Machine Learning, and Deep learning algorithms, these companies significantly improved their product packaging processes, detecting defects and irregularities.

For instance, Nestle SA has expedited its product development process by 60% since 2016, enhancing operational efficiency, while Coca-Cola optimized quality inspection, reducing waste, and boosting sustainability.

Conclusion

Wrapping it up, adopting Vision AI in Carton packaging can truly transform the way companies operate, propelling them towards a secure, eco-friendly future. Its innovative features such as real-time visibility and enhanced safety, carve a sustainable path forward for the industry.

As consumer demands continue to evolve and environmental consciousness reshapes the packaging industry, incorporating Vision AI in Carton Packaging is not merely an option but rather a transformative leap forward. By embracing this technological innovation, companies can maintain a competitive edge and effectively cater to the ever-changing market demands.

Contact us now to discover how Vision AI can transform your packaging quality standards!